In every product development story, there is always a question of the product’s response to the operating environment – it may be temperature, fluid, operating forces, vibrations, etc. To validate the structural integrity of the system in the prospect of Design and Working Loads – We could use Finite Element Analysis to validate, when it on the prospects of fluid flow, Thermal behaviour and fluid loads – Computational Fluid Dynamics comes into the picture.

What is Computational Fluid Dynamics?

Computational Fluid Dynamics (CFD) is a part of computer-aided engineering – simulated the fluid flow and thermal behaviour inside a defined boundary. The results quantify various flow parameters like velocity, turbulence, vorticity, temperature etc. and provides us with deep insight over the problem and help us to optimize the flow characteristic based on our requirements.

Why CFD

Static fluid problems can be solved through formulae and would be the same in the applied environment due to its limited variables. In the case of fluids in motion, the scenario completely changes to the other extreme due to many variables involved. Turbulence makes the condition even worse. The complex dynamics of the fluid flow and Turbulence are solved only through computational methods. Through CFD, we could find the flow behaviour and its characteristic parameters to optimize them for better functionality and performance.

By using Computational Fluid Dynamics (CFD),

We get the insight of the physics and flow parameters which are not possible in the experimental conditions to visualize.

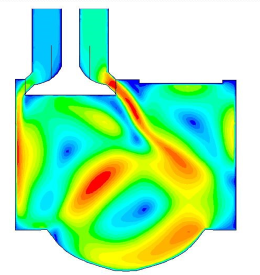

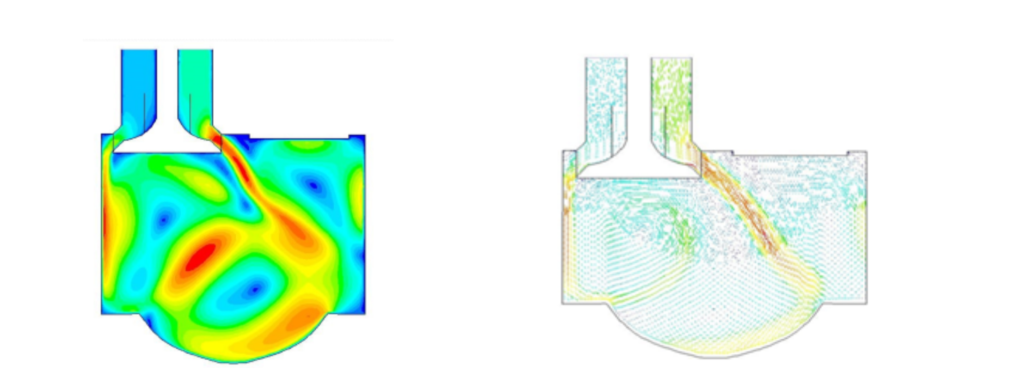

Case: We could not view the mixing of fuel-air inside the combustion chamber while the engine is ON, but CFD provides the insight to capture the transient performance and mixing efficiency inside the chamber and quantify the parameters.

Fig: Mixing in Combustion chamber

We get the foresight to the various fluid structural loads and helps us to quantify the structural integrity over the years to resist fatigue and creep failures

Case: Aerodynamic failures are very intricate and hard to predict. Tacoma bridge is one of such examples that collapsed due to aeroelastic fluttering. CFD simulation enables to evaluate such scenarios and pave the better way of engineering.

Time and Cost plays a vital role in the development of any product. Evaluating the product concepts through tandem prototyping and testing takes time and expensive. Virtual validation using CFD reduced lead time and inexpensive.

How CFD works?

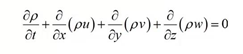

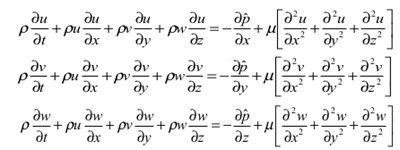

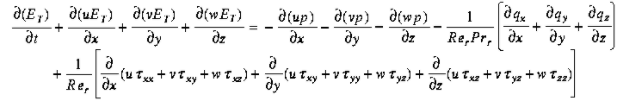

Computational Fluid Dynamics computes the fluid dynamics and thermal flow by numerically solving the discrete form of the governing equations.

Conservation of Mass (Continuity Equation)

Conservation of Momentum (Navier-Stroke Equation)

Conservation of Energy

There are lots of tools and software in the market to run CFD analyses and acquire results of some sort but it requires experience and in-depth knowledge in dynamics and products to quantify, validate and provide the finest engineering solutions. Graphler technologies, provides CFD Analysis services in India with 360-degree solution in product design and development, FEA, CFD, and Manufacturing.

Graphler Technologies , one of the leading product design companies in India we also specialized in many sectors like Heavy Engineering design services, FEA Consulting services, 3D Modelling Services India and in 3D CAD design service In India.