If you have a Product with fluid flow or heat transfer, can you afford not to use CFD in your design process?

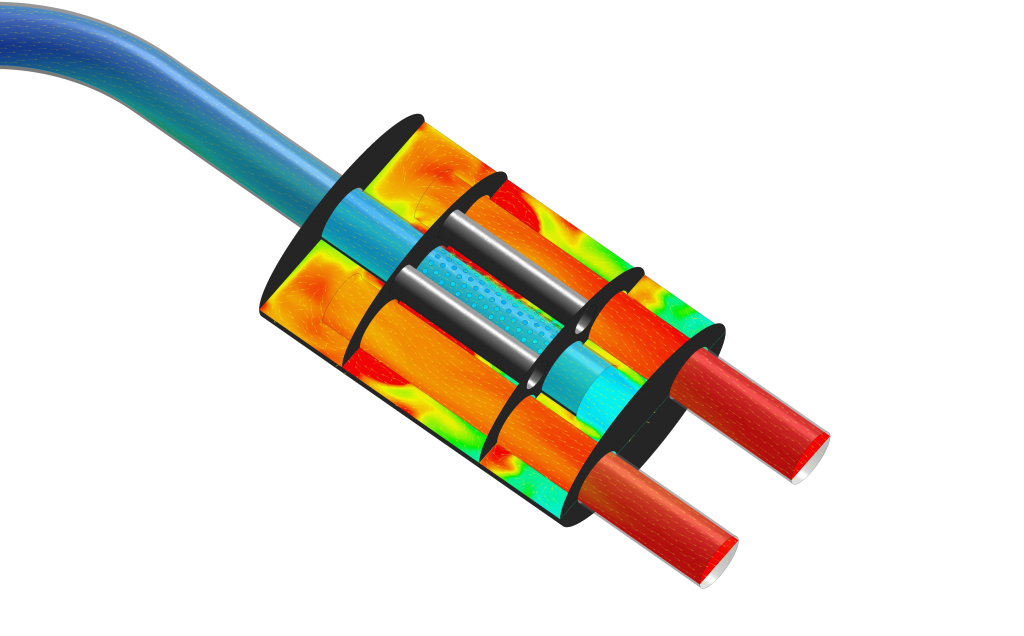

Conjugative Heat transfer Analysis (CHT)

CHT or Conjugative Heat transfer Analysis can accurately predict by simultaneously solving heat transfer through solids and fluids.

(CHT) is a combination of heat transfer in solids and fluids by exchanging energy at the interface between them. In solids conduction always dominates and in fluids convection always dominates.

Effectively combining heat transfer in solids and fluids is the key to designing several Industrial applications. This study enables to understand the heat transfer co-efficient, heat flux rates, identification of localized hot-spots in systems, evaluation of temperature peaks etc.

To know more Click here to connect or visit our Blog

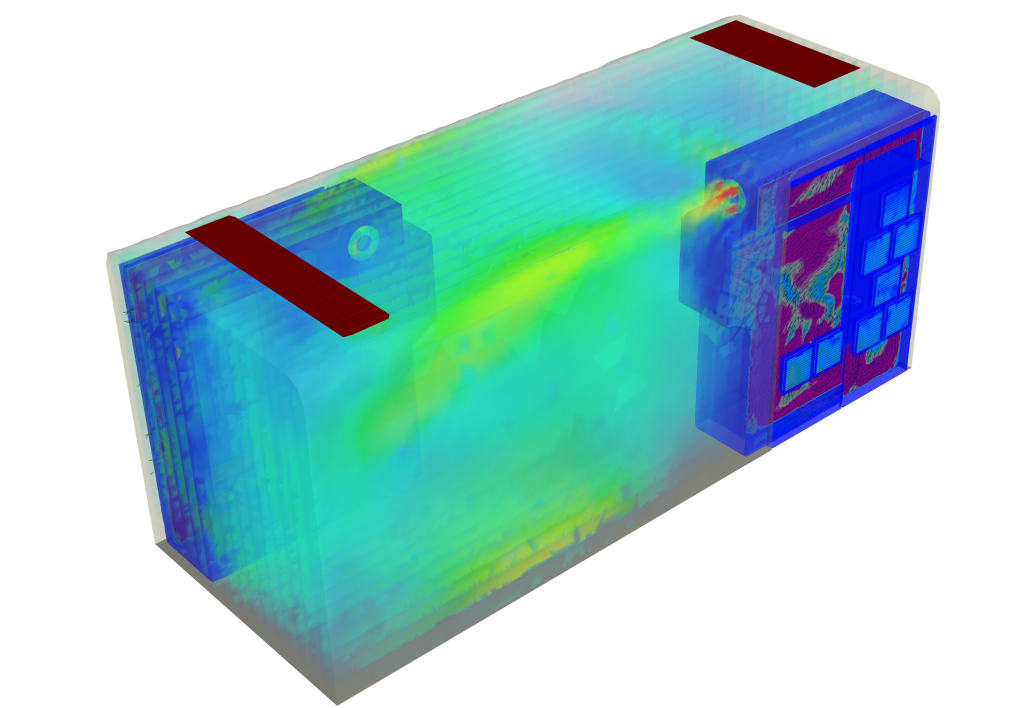

Transient Analysis

Transient or time-dependent or time stepping analysis is conducted when the system’s boundary condition changes with respect to time. Almost every system changes with time, it is used to capture insight into time-varying flow features or phenomena which would otherwise be difficult to capture in physical testing.

For any transient simulations, it is important to select appropriate time step required to capture the flow physics, too large a time step will result in lost detail and a time step which is too small will increase computational efforts. A right physical model, time step size and user-defined functions (UDF) is appropriate to capture the physics with fewer approximations.

To know more Click here to connect or visit our Blog

Internal Flow Analysis

CFD internal flow analysis is most widely performed analysis type which can accurately predict the behaviour of fluid flow in any bounded volume system for example – pipe lines, plenums, valves, HVAC ducts, heat exchangers, orifices etc.

This type of CFD study can provide comprehensive set of data which gives significant insight into performance of the system and optimizing it. The following objectives can be identified with CFD internal flow analysis –

1.Flow distribution and optimization

2.Pressure drop analysis

3.Evaluating heat transfer rates

4.Identification of flow circulation and separation region

5.Evaluating air exchange rates or ACPH

To know more Click here to connect or visit our Blog

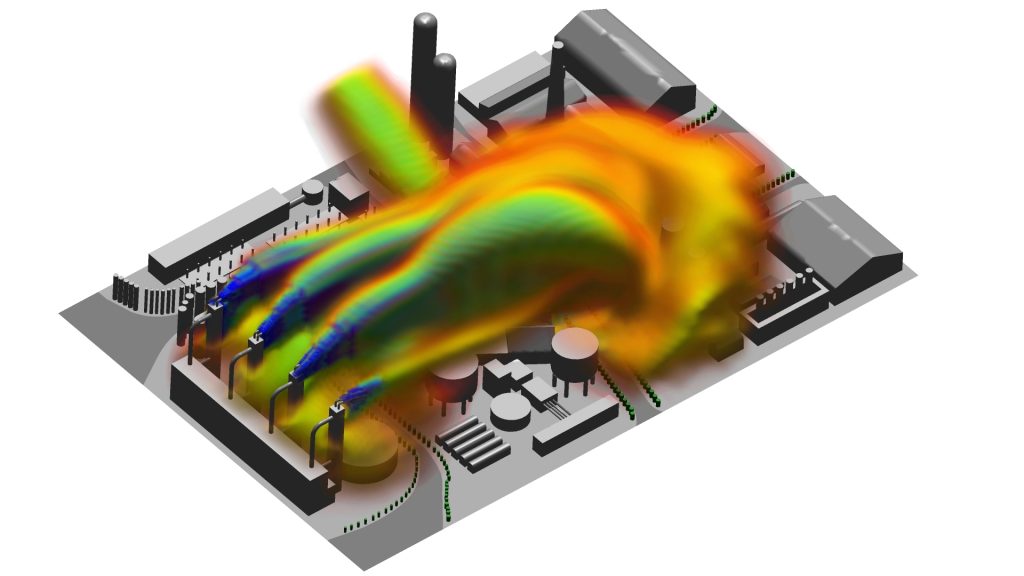

External flow analysis

CFD external flow analysis can accurately predict flow behavior of fluids over bodies. It has very wide range of applications and it ranges from evaluation of building emission dispersion to a highly compressible flow phenomena of fighter jet.

A full-scale CFD simulations can be performed over complex geometries generating insights into flow behavior around bodies thus providing significant advantages when it comes to validating or optimizing designs.

The following objectives can be evaluated in this study –

1.Identifying load induced on the system due to wind

2.Virtual Wind tunnel study

3.Visualization of bounded flow over objects

4.Evaluation of drag and lift induced forces

5.Evaluating temperature fields over objects

6.Dispersion of emissions

To know more Click here to connect or visit our Blog

Fire Dynamic Simulation (FDS)

FDS is a fire driven fluid flow analysis, it demonstrates the propagation of fire inside a building, Industry, Metro station, Basement car parking etc. the results from FDS plays a key role in –

1.Fire propagation and intensity

2.Placement of fire suppression systems

3.Management of smoke ventilation systems

To know more Click here to connect or visit our Blog

Moving geometries

It is the simplest steady-state numerical modelling methodology available to predict the behavior of fluid in rotating or stationary systems. Moving reference frame (MRF) is a technique employed to predict fluid flows in turbine, impellers, blowers, stator, compressors etc.

The analysis helps developers to understand from the bulk of information –

Visualization of flow over turbine blades

Pressure distribution on blade surface

Performance analysis

Windage loss prediction

To know more Click here to connect or visit our Blog

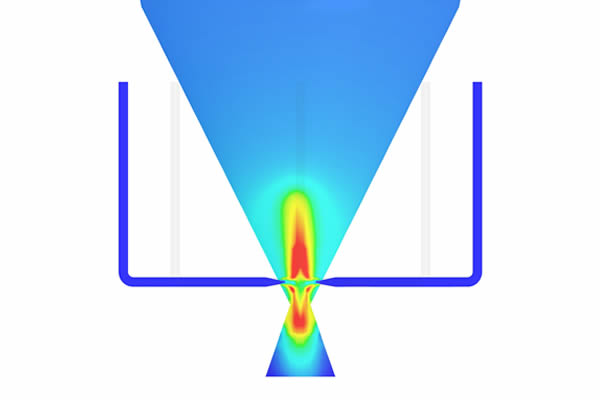

Multi-phase flows

CFD can be used to accurately predict Multi-phase flow behavior of fluids discretely dispersed in continuous phase of main fluid domain. Multi-phase flow studies are inherently complex to model in CFD and hence more understanding is required in approximating boundary conditions when it comes to simulating and optimizing these flow systems. We have performed particle to particle and phase dispersion transport analysis for clients across industries.

We have expertise in Industrial applications such as –

Nozzle spray

Contaminant migration inside buildings

Dirt deposition

Erosion analysis

To learn more about our expertise in solving Multi-physics, write to us.

Species transport

CFD simulations of reactive flows are necessary to understand the kinetics and analysing this behaviour helps designers to gain insight and more informed design decisions. Species transport is among the complex numerical models with chemical reactions, multi-phase flows and particle tracking (Discrete phase).

With prior experience in solving for Combustion chambers, furnaces, burners and heaters. Our project expertise includes solving for –

Reacting flows

Combustion in IC engines, furnaces and burners

Formation of emissions or burnt mixture

Temperature fields and heat transfer rate in flame zone

To know more Click here to connect or visit our Blog

Discrete Phase

A Discrete Phase numerical model in CFD is developed to understand the flow of particles (Discrete phase) in a continuum or a fluid medium. Various Industrial applications and processes involves fluid and particles in one system.

Our prior experience in solving includes –

1.Air filtration

2.Spray coating

3.Catalytic converters

To know more Click here to connect or visit our Blog