Design. Validate. Build

Product Prototyping and Manufacturing

Prototyping plays the vital role in converting the virtual model into Physical output. Prototyping is the final and an important aspect in Product development processes. Whether our scope is to explore new design concepts or redefine existing design or explore different manufacturing options, prototyping is an important tool.

Graphler is a trustful partner for creating Product Mock-ups and Prototyping testing services and with our experienced engineers, we have helped small, medium and enterprise level clients by helping convert their ideas into reality.

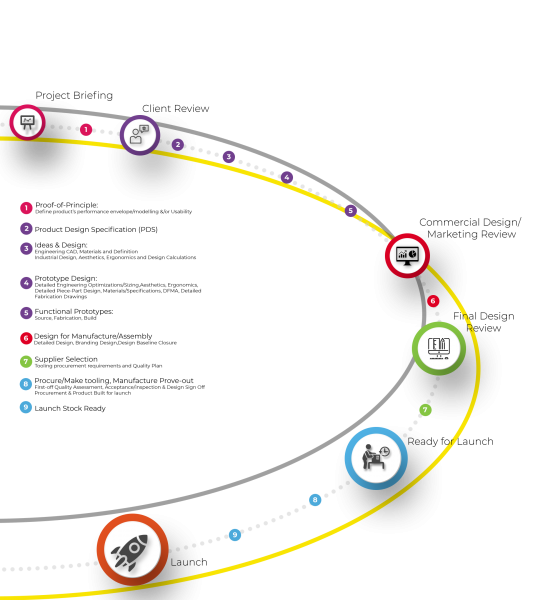

All Product companies has to respond quickly to market demands for new products. Under this requirement, the competitiveness of the Product company lies in verifying the design by creating the prototype, and make new product ‘go to market’ faster.

Before moving to mass production, it is imperative to verify the product prototypes of all parameters, including Concept models, Functional prototypes, Engineering prototype and Low volume manufacturing. Appropriate utilization of prototyping strategies can make the development process more dynamic and effective and there by reducing the chances of Product failures.

The following are different prototypes which we offer

Proof-of-concept Prototype

This type of prototype is developed to validate if the Product ideas are met and fully understood the critical design intent. These prototypes can also help the designer to communicate effectively with engineering team and let any design issues be discovered and resolved before the engineering prototypes are built.

Display only Prototype

This type of prototype is developed simply to show off the visual and aesthetics aspects of the product. However, this prototype does not hold any engineering or functional validation, whereas this could be used for display in Trade shows or for Product photography to check market acceptability.

3-D Printing and Rapid Prototyping

3D Printing is the least time consuming of all prototyping methodologies and could be best way to build and check aesthetics as well functional aspects of prototypes before any investment is made in tooling. Rapid prototyping is more useful in developing small and scaled model of products with very less time than any other prototyping techniques. This shall also be effective in communicating the concepts designs to Management, Clients etc.

Engineering Prototype

This type of prototype is developed to understand the product critical and functional aspects of the design. This prototype is also the perfect sample of a ‘go to market’ product. During its development we can understand and study the manufacturability, ease of manufacturing, machine tolerances, duration, man-power, supply chain effectiveness etc. The engineering prototype can also be used to lab test for various environmental, functional, external load conditions or comply with any other test standard. The various test results can be interpreted to make critical decisions before actual investment is made for full scale manufacturing.