Introduction

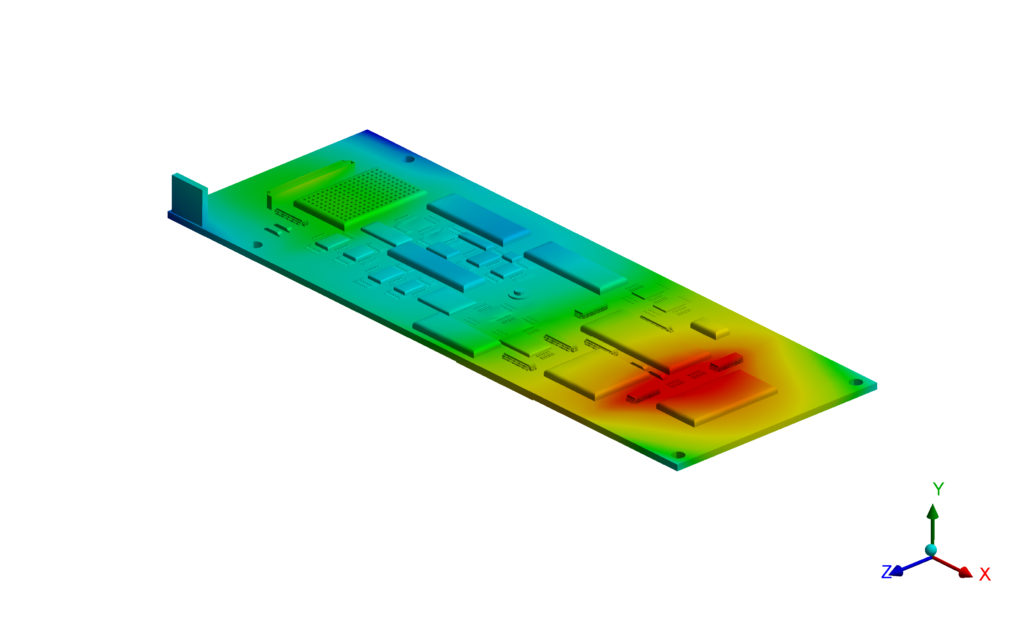

Thermal analysis is a technique in FEA, where the numerical model solves the thermal equations using the thermal properties or loads defined by the analyst. It is useful to analyze problems such as heating/cooling of electronic components or the heating of EV batteries. Thermal analysis can give you an understanding about the assembly and part level thermal stress, expansion, and contraction behavior. In FE thermal analysis there is two ways to approach it – steady-state and time-dependent transient analysis. Below we have discussed on the use cases of different thermal analyses approaches –

Steady-State Thermal Analysis

In a steady-state analysis, the problem is defined with no meaningful time scale. The internal energy is ignored or simulation solves until it reaches equilibrium. In some FE tools, we can specify a time incremental or a time period, but it does not have anything to mean with real-world time. This type of approach is similar to an implicit method of solving in structural FEA. The time period linearly changes boundary conditions applied to it.

In steady state thermal analysis, the thermal conductivity of the material is only required to run the simulation. Since steady state only solves governing heat transfer equation when dT/dt=0 or just until the system reaches equilibrium.

Transient – Thermal Analysis

Unlike in steady-state thermal analysis, transient analysis takes into account the time variability in boundary conditions. It is more like an explicit approach in structural FEA. Like an explicit method, transient thermal analysis requires boundary conditions to defined with respect to small increments in time to properly capture the time-dependent thermal behaviour in the system. Any analysis that can be run as a steady-state simulation can also be run as a transient simulation, as the each step in transient simulation will converge to the as a steady state solution before moving on to the next time step and so on. However, this is very time intensive to solve, so it is generally preferred, if a problem can be approached as a steady-state thermal analysis unless it is needed based on the below criteria –

So when can one prefer to use Steady-state or Transient simulation techniques –

Use Steady-state when:

- Loads are not time-dependent or does not change with time

- Results are required only when solution reaches an equilibrium condition

Use Transient when:

- Loads vary with time

- Effects of time are important

- Results are required at any specific time interval

- Non-linearities to considered in the problem

Conclusion :

Graphler Technology is one of the fastest-growing product design companies in India. Our FEA Consulting services hold great promise for future trends. We have a team of experts specialized in Pressure Vessel Analysis Services, CAD Conversion Services, 3D to 2D Conversion Services, and also in Product Animation Services.

Contact our experts today to know about our services.