Introduction:

In recent years, stringent indoor air quality and thermal comfort is gaining importance in design of Industrial buildings. This study aims to find the optimal ventilation system and designed intently to improve energy efficiency and indoor air quality. CFD codes were used to simulate every category of the industrial complex in order to validate the actual building in a typical summer day and the results were compared.

Scope for CFD Analysis

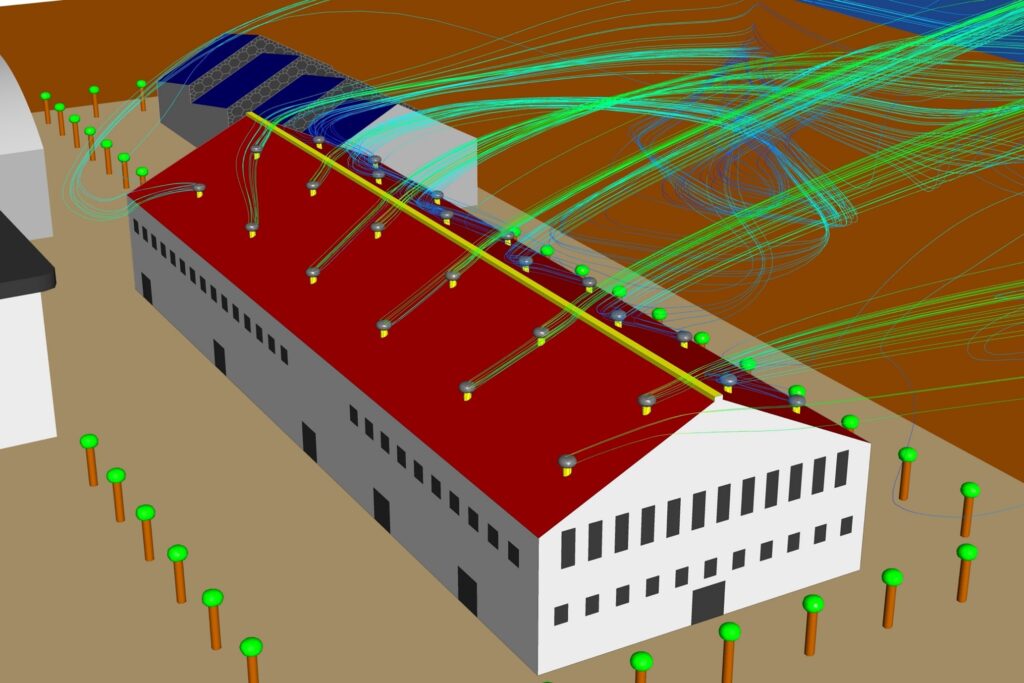

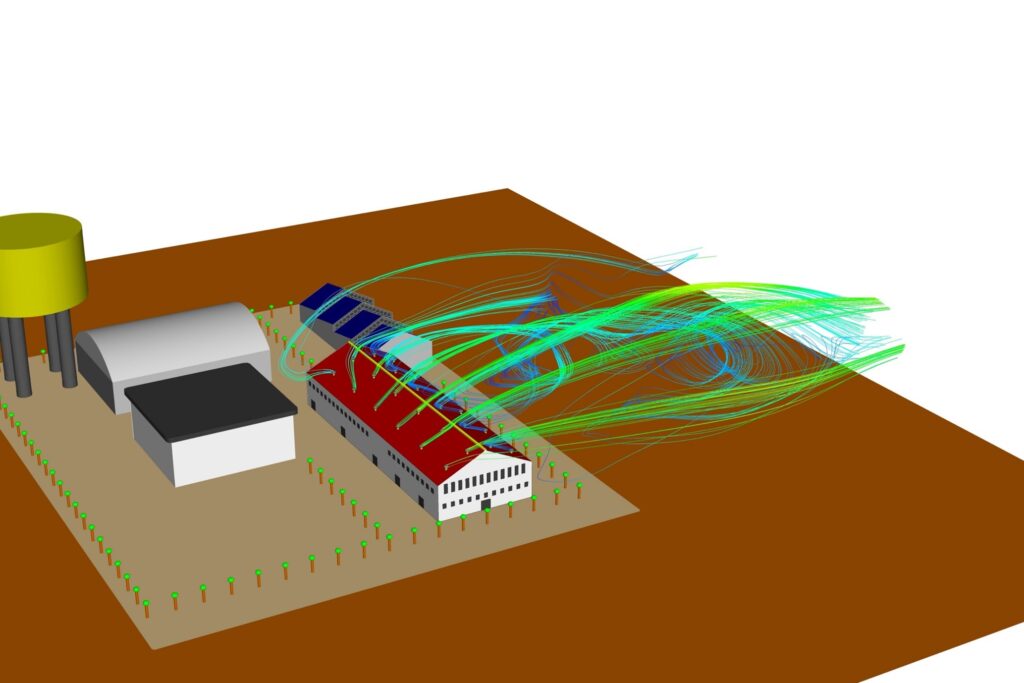

- To compare and evaluate the ventilation effectiveness of Turbine ventilators vs. Centrifugal upblast ventilators.

- To discharge exhaust air to eliminate interference with other equipment or human activity.

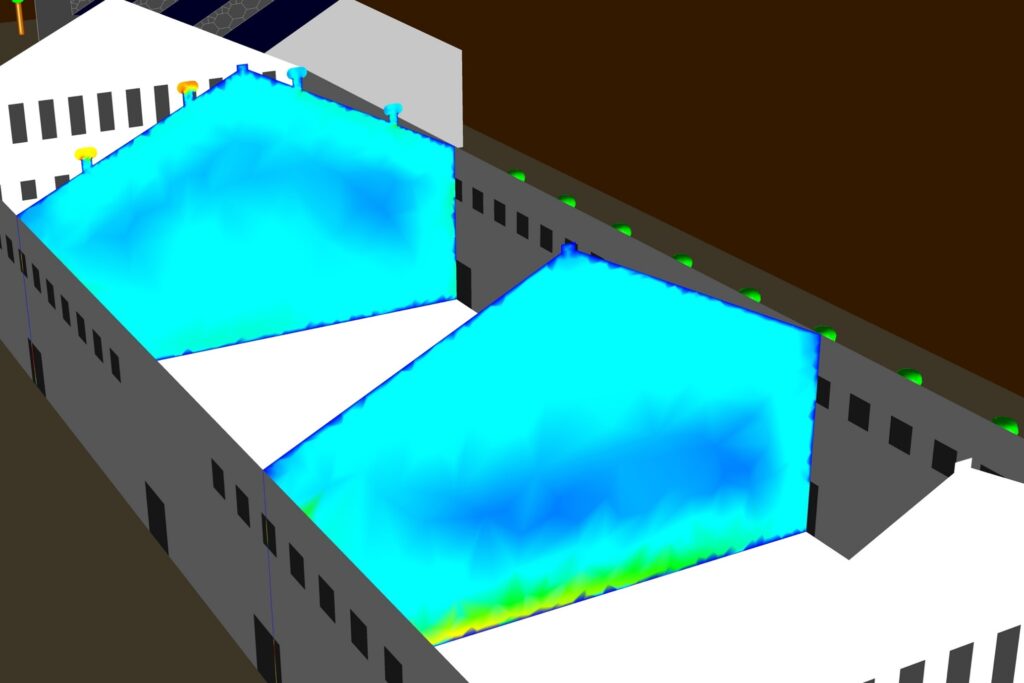

- To understand the flow pattern inside the building and position the ventilators to get the desired ACPH (Air Changes per Hour).

- Thermal distribution at the working plane (150 cm from ground) to determine human comfort level.

The conditions –

| Parameter | Values |

| Area of target building | 25,560 Sqft |

| Total area of Industrial complex | 80,000 Sqft |

| Process heat load | 150 KW (Averaged from various sources) |

| U-Value of Galvanized Aluminum Steel sheet | 1.45 BTU/hr-Sqft-F |

| Ambient Temperature | 37 C |

| Ambient pressure | 1 Atm |

| Wind velocity | 3.5 m/s |

Our approach and methodology –

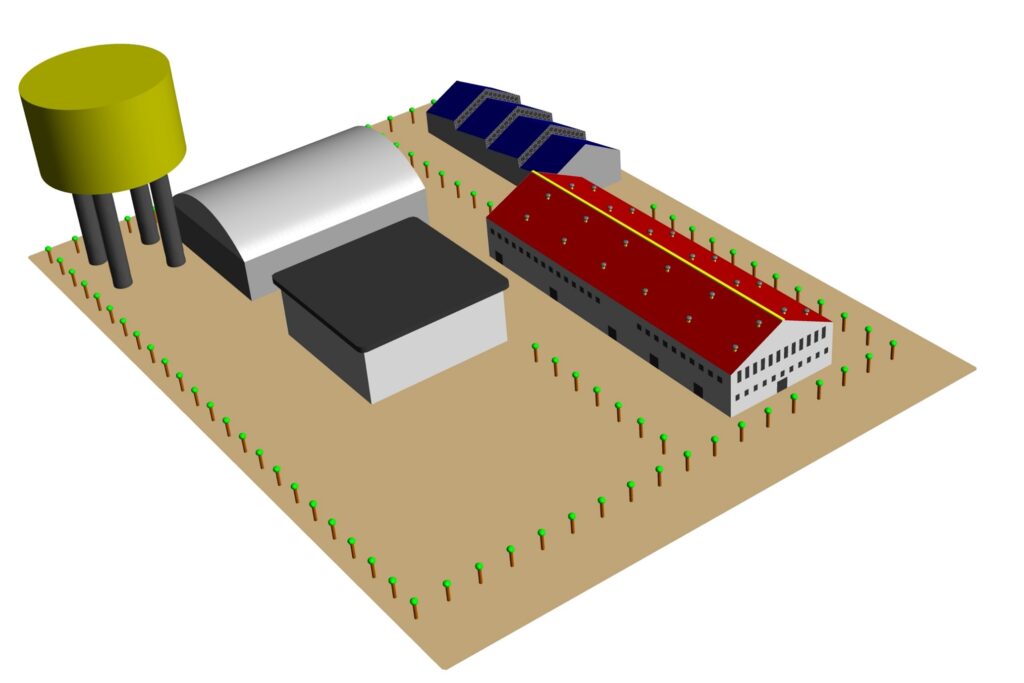

- The whole industrial complex is modelled as per 2-D draft sheets and material properties assigned as per specifications.

- Trees, tarmac roads and landscape are considered for the analysis since the roughness can disturb the flow.

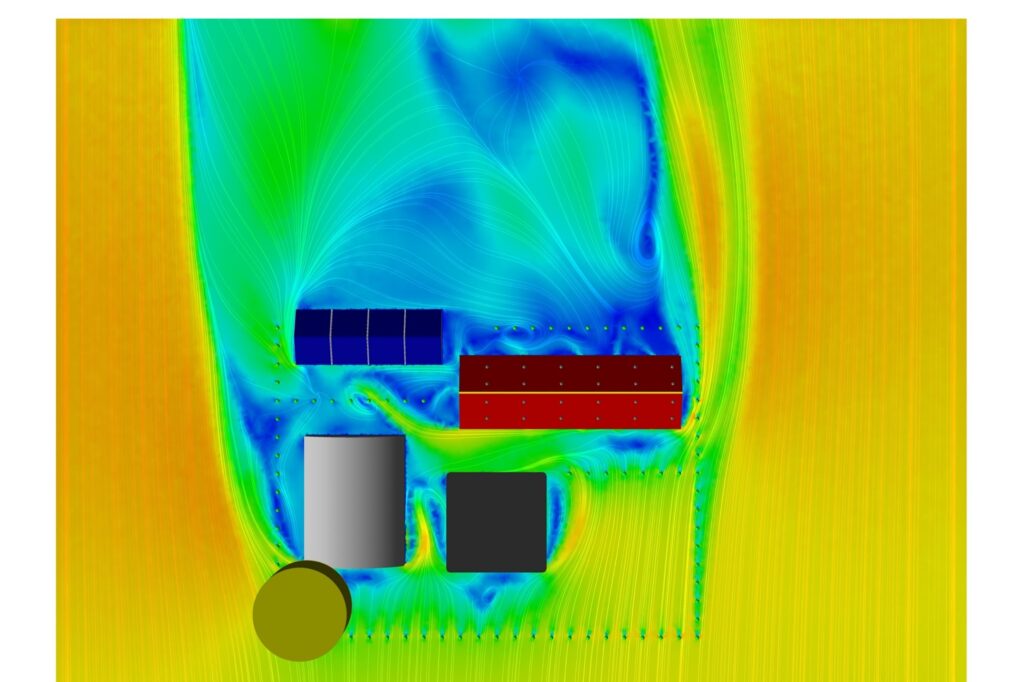

- Large Eddy Simulation (LES) turbulent model is used since the feature can solve explicitly for larger eddies and also solve for smaller eddies, swirls and vortices by using Sub-Grid Scale model.

- Wind tunnel around the Industrial complex is modelled as per standards to simulate real case scenario.

Conclusion –

With more complex designs, stringent safety requirements and ever-increasing energy concerns, designing for Energy efficient manufacturing units has become critical for Architects and LEED consultants. Using CFD empowers Engineers to optimize building design, especially in early stages when changes can be implemented efficiently and cost-effectively.

In this Case study, we were able to provide sufficient insight into occupant comfort level, indoor air quality, temperature, heat loss and solar heat gain through the structure and compare it with different ventilators and positions.

CFD simulation is a powerful tool that can accurately predict ventilation behavior in manufacturing units. This technology enables engineers to simulate and analyze the airflow, temperature distribution, and contaminant dispersion within the facility.

At Graphler Technology solutions, we provide industry-leading CFD Analysis Services, CAD Conversion Services and Pressure Vessel Analysis Services. We can help manufacturers to optimize their ventilation systems for improved air quality, worker comfort, and energy efficiency. With the power of CFD, many companies can make informed decisions about their ventilation systems and improve their overall manufacturing operations.