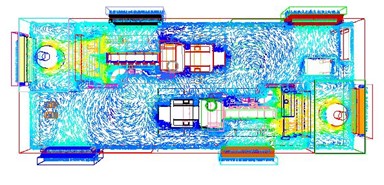

Heat ventilation is a main requirement of shelter canopies. Diesel Generator coupled with alternator are the main source of heat in the chamber and it is very important to handle the thermal behavior inside the canopy utilizing free and forced cooling strategies with reduced energy utilization, lowest aerodynamic noise and noise escape from the chamber produced by the engine. Base case analyses were done to identify the hot spots, recirculation and the natural heat transfer coefficient for the existing model.

Heat calculation were made to determine the sources of heat and the priority to provide high rate and low rate of cooling which would enable optimized efficient cooling module with low energy utilization.

Louvers were provided with variety of profile parameters and were modified to achieve easy fluid movement with least aerodynamic noise and reduced noise escape.

Noise Baffles profiles and positions were iterated to provide reducing the noise level inside the shelter and which were also maintained not to provide space for thermal stagnation. ACPH rate and heat convective rates were calculated to identify the best optimized pattern of iterations.Fans were placed with optimized position and pressure drops to avert hot spots and improve ACPH.

Approach:

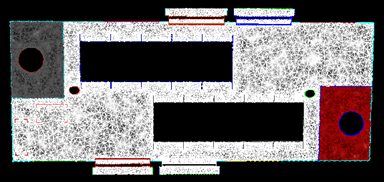

- The Computational Fluid Domain were extracted from the CAD model and are cleaned up for issues.

- The model is then discretized with high quality meshing strategies adhering for most accurate results with good compatibility to convergence of solutions.

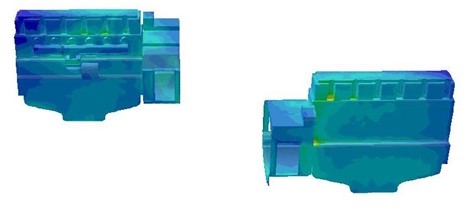

- Then the boundary conditions were applying to inlet outlet and the sources with heat generation rate to enable the exact virtualization of real scenario.

- Expertise modification and parametric iterations were made to achieve the objective from the post processed results.

Conclusion:

- Through the process of ALD, utilizing CFD ventilation effectiveness inside the shelter is evaluated.

- Hot spots, recirculation region and thermal distribution in the shelter is evaluated.

- The hydrodynamic and thermal behavior of the shelter assembly is validated for field conditions.

By integrating CFD consulting services, structural design services, and collaboration with product design companies, the analysis and optimization of the DG shelter’s ventilation system were conducted thoroughly. This holistic approach ensures that the shelter is not only functional but also durable and reliable, meeting the stringent demands of real-world applications.