In modern engineering, Computational Fluid Dynamics (CFD) is vital for optimizing thermal systems. This blog explores a recent CFD thermal analysis performed by Graphler Technology Solutions to evaluate a heat exchanger’s efficiency in transferring heat from a hot fluid (MSW slurry) to a cold fluid (DM water). Here’s what the study uncovered:

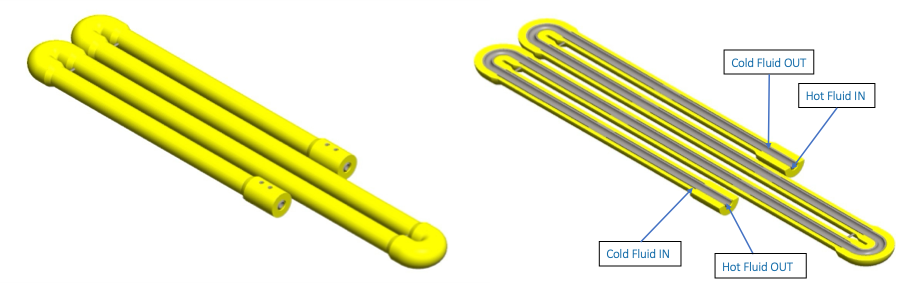

The Study Setup

The analysis simulated the heat transfer dynamics between two fluids using steady-state Conjugate Heat Transfer (CHT) analysis. Key parameters included:

- Hot fluid (MSW Slurry): Initial temperature of 400°C, flow rate of 0.5 LPM, and inlet pressure of 300 Bar.

- Cold fluid (DM Water): Initial temperature of 10°C, flow rate of 38.61 LPM, and inlet pressure of 2 Bar.

The system comprised four heat exchange passes, designed to ensure progressive heat transfer and achieve target temperature levels.

Key Findings

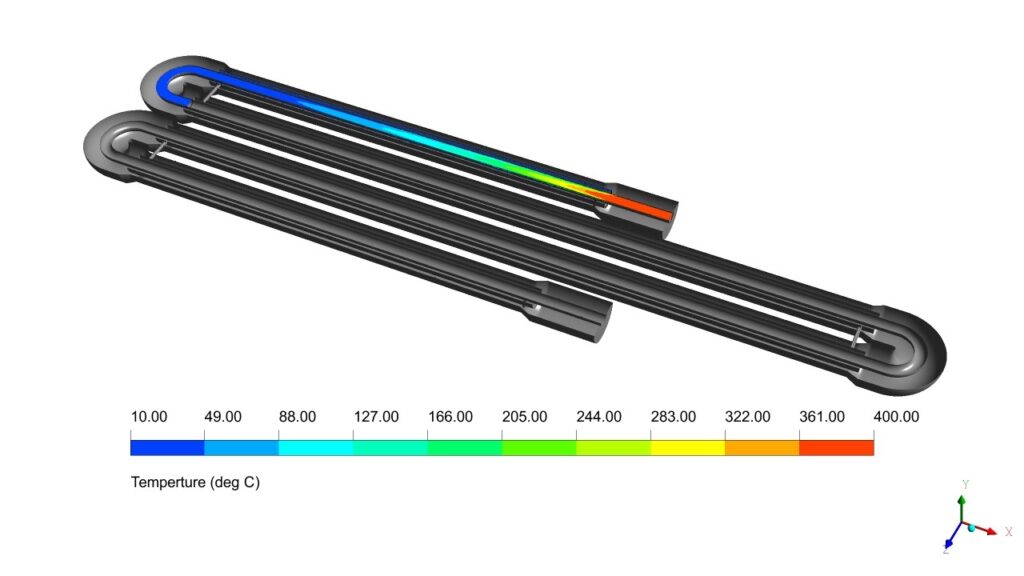

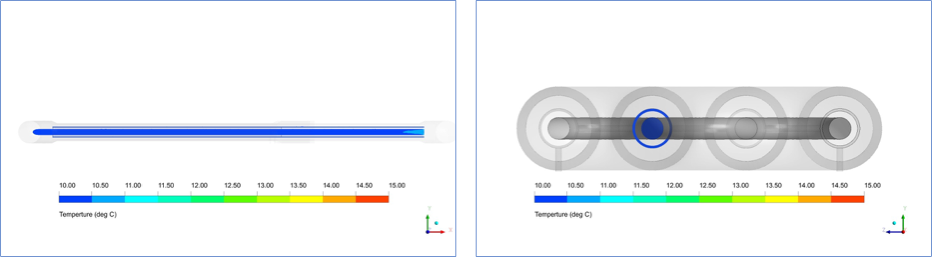

- Temperature Distribution

- In Pass 1, the hot fluid’s temperature dropped significantly from 400°C to 29.86°C.

- Subsequent passes refined the output temperature, with Pass 4 reaching equilibrium at ~10°C.

- Heat Transfer Efficiency

- The cold fluid flow rate was 77 times higher than the hot fluid’s, driving an aggressive temperature drop.

- The heat exchanger required approximately 9–10 meters to align the hot fluid’s temperature with that of the cold fluid.

- Material Effectiveness

- Stainless steel (Grade 304) and rockwool insulation ensured thermal integrity, with average heat transfer coefficients of:

- Cold fluid side: 1027 W/m²-K

- Outer insulation: 454 W/m²-K

- Stainless steel (Grade 304) and rockwool insulation ensured thermal integrity, with average heat transfer coefficients of:

- Energy Implications

- The design successfully minimized thermal losses while maintaining the structural and thermal stability of the exchanger.

Design Recommendations

- Material Selection: The use of rockwool insulation and stainless steel proved effective. For future designs, these materials should remain standard, especially for similar operational conditions.

- Flow Rate Optimization: High cold fluid flow rates were critical to achieving rapid heat exchange. Depending on energy costs, optimization between flow rates and exchanger length can be explored.

- Length Considerations: A total pipe length of 18 meters, with four sequential passes, was adequate for the temperature targets. This insight aids in reducing unnecessary material and space usage in similar designs.

Reach out Graphler technology for a CFD Consulting Services .We are also specialized in Stress Analysis Services , Structural Design Services and more.