Introduction:

The mixed-flow submersible pumps are used for domestic purpose and also at the commercial level in a large extent, so increasing the efficiency of the pump is an essential part. Design of multi stage pump is really complex due to the fact that the flow inside this pump is inherently complex in nature. With the rapid development of the computer technology, the Computational fluid dynamics (CFD) and the numerical simulation has become an important tool to study flow field inside the pump and predict its performance.

With the aid of the CFD technology, the complex internal flows in water pump impellers can be well predicted and speed up the design procedure. Thus, CFD is an important tool for pump designers since it will reduce the time consuming and expensive experimental procedures.

Scope of Work:

- Predict the performance improvement of Bowl-Impeller Axial Gap in a multi stage mixed flow submersible pump.

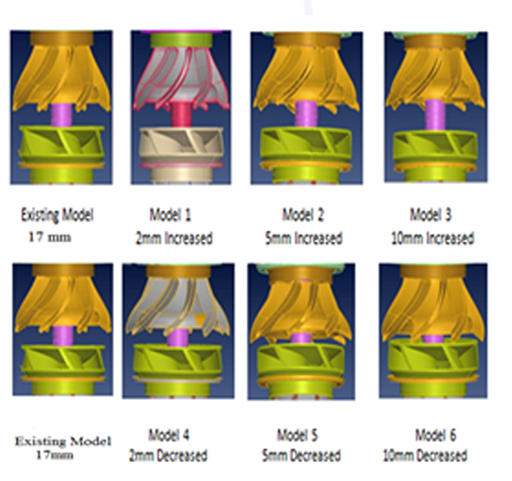

- Six different Bowl-Impeller axial gap variations were considered (vary from 2mm, 5mm and 10 mm in Increasing and Decreasing order ).

- Taguchi Method is utilized to reduce the number of trials and to optimize the best performance.

With a goal of increasing hydraulic efficiency of the pump CFD is utilized in a following systematic way.

Validation Study: CFD procedure has lot of variables such as grid count, turbulence model, and discretization scheme, so it is important for a CFD engineer to play between those variables without affecting the solution accuracy.

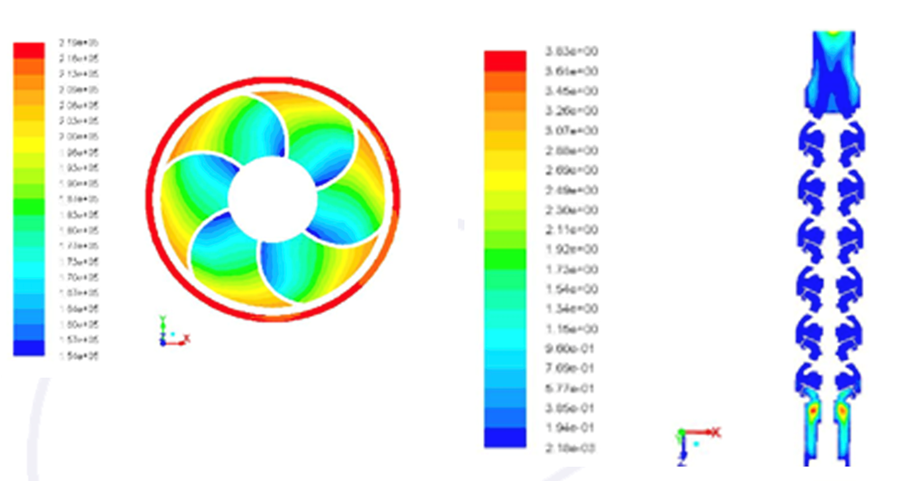

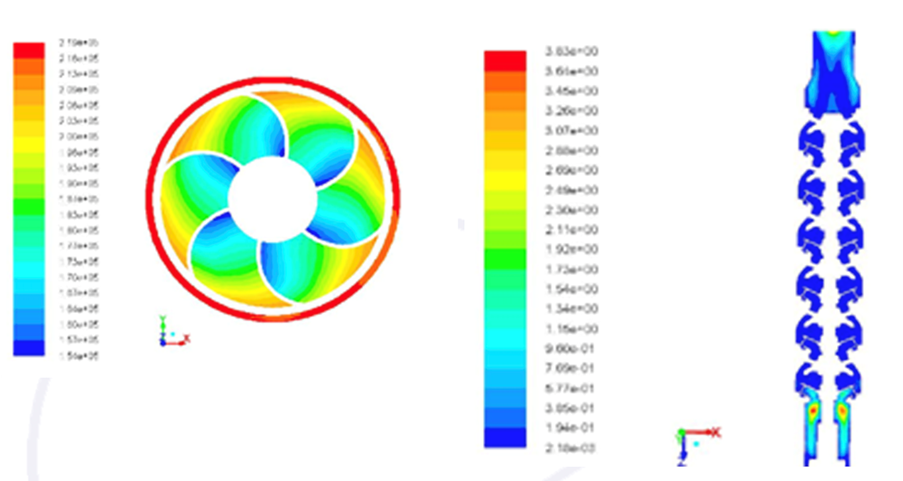

A commercial Computational Fluid Dynamics (CFD) code with a k-£ Realizable turbulence model was used to study the effects of Bowl-Impeller Interaction. Moving Reference Frame (MRF) technique is used to numerically model the rotation of the impeller section to predict the flow behaviour of the pump.

The numerical results are compared with the experimental data of the base model to arrive at the best computational procedure (BCP). Consult a reputable CFD consulting service or an Engineering Animation Services company to gain precise knowledge.

Performance Enhancement Study:

The hydraulic performance of the pump highly depends upon the complex configuration of the Bowl-Impeller interaction, number of blades on bowl-impeller, inlet-outlet angles, radial and axial clearance between Bowl-impeller and other various dimensions such as diameter, width etc., In this case axial clearance, number of blades and outlet angle on impeller are taken as the major variables for optimization.

Utilization of DOE Methodology

Taguchi method is a scientifically disciplined mechanism for evaluating and implementing improvements in products, processes, materials, equipment, and facilities. These improvements are aimed at improving the desired characteristics and simultaneously reducing the number of defects by studying the key variables controlling the process and optimizing the procedures or design to yield the best results.

Graphler Technology Solution provides the best Stress Analysis Services in Coimbatore. They have well expertise team with 10 yrs of industrial knowledge. For further information, please get in touch with us. We are always here to help you out.