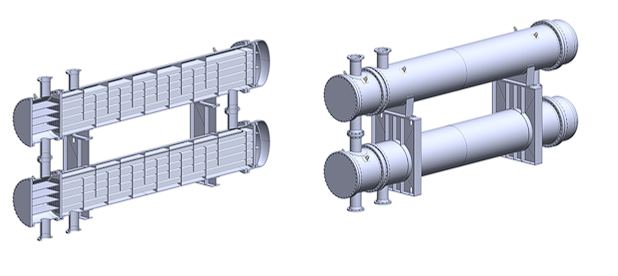

Our client is a leading manufacturer and supplier of Shell & Tube, Plate type Heat exchangers, Boilers and Pressure vessels. The client’s requirement is to design ’Floating Head Heat Exchanger’ in compliance with ASME Sec VIII and TEMA class S specifications.

We at Graphler Tech was appointed to design detailed 3D model, prepare General arrangement, Fabrication drawings and to issue detailed drawings for various components in the Heat exchanger

What we Delivered:

- 3D CAD Model as per Client’s requirement/specifications

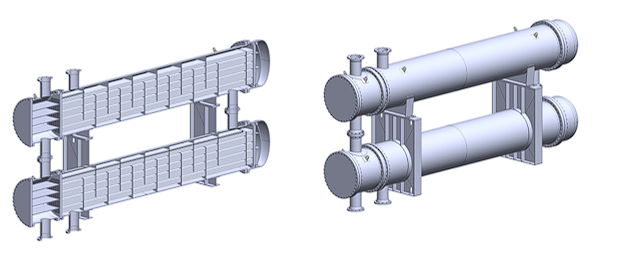

- General Arrangement Drawings

- Fabrication drawings

- Machine drawings of various components

- Parts drawings of various components

- Detailed Bill of materials

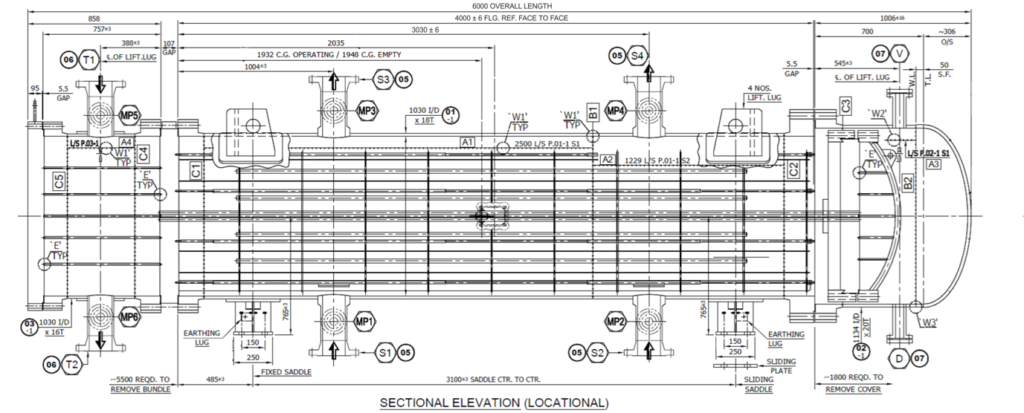

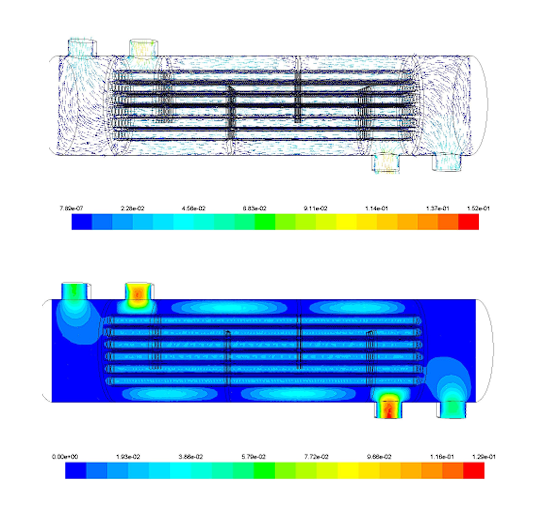

- CFD simulations to ensure customer’s design criteria is met

- FE simulations to ensure structural integrity during lifting, transportation.

Design Specifications:

- The Floating Head Heat Exchanger is designed for:

- Pressure rating: Shell side: 38 kg/sq. cm, and Tube side: 30 kg/sq. cm

- Temperature rating: Shell side: 150 °C and Tube side: 110 °C

- Fluid capacity, Shell side: 2.8 cu.m., and Tube side: 1.8 cu.m

- No. of passes: shell side (cross flow) and tube side (10).

- Design wind reluctance: 50 m/s as per IS 875 Part 3

- Seismic design code: IS: 1893-2005

- Insulation thickness is 15/50 mm.

- Gross weight of Heat exchanger (empty): 13 tons

- Through simulations, we were able to provide nozzle loads, wind seismic data, bolt torque and forces, and welding stresses and forces.

- Detailed drawings were provided to Davit for cover, insulation clatters, tube bundles with tube-to-tube sheet joints, tube layouts, baffle layouts, tie roads, girth flanges, passage partitions, gaskets, hold points, name plates, etc.

- Finally, all design information, like native 3D CAD data, drawings and simulation reports, was submitted to the customer.

You can come up with new routes by teaming up with a leading Stress Analysis Services Partner or Product Design Companies with a good reputation.

CFD Analysis validation:

CFD simulations were performed to understand the velocity and temperature distribution on Shell and tube side. The heat exchanger was simulated with operating temperature and pressure. The intensity of turbulence, heat transfer rate was studied and the results are reported to ensure that the design is in compliance with requirement and efficiency of the system is achieved.

The best way to obtain the accurate information is to consult an experienced CFD Consulting Services or Structural Analysis Services provider.