Is Design by analysis required to design a Pressure vessel?

To be precise in most situations, you probably need not use FEA to design your pressure vessel. The rules for designing pressure vessels is clearly laid out in ASME Section VIII, Division 1 and ASME Section VIII, Division 2 and they have a long history of successful application. However, in some situations where the calculations alone shall not satisfy to validate a specific design geometry or load which may necessitate the use of FEA.

What is design by analysis?

Design By Analysis, as described in ASME Section VIII, Division 2, Part 5 is an approach for validating the adequacy of a pressure vessel component design. It provides detailed rules for performing different analyses and provides different loads and load combinations for which has to be considered. The entire approach centered in Design By Analysis philosophy is on the Protection Against Failure Modes of the Pressure vessels. There are four failure modes that require attention:

- Failure due to Plastic collapse

- Failure due to localized stress

- Failure due to Buckling

- Failure due to Fatigue or cyclic loading

For each failure mode, the FE analyst is presented with multiple options of how to perform the analysis that would help to mitigate the dangers of specific failure mode. In general, these options involve an Linear method and a Non-Linear method of Analysis. In case of a Plastic collapse simulation, the analyst can use the Linear method which uses an Allowable Stress Design (ASD) approach, whereas the Non-Linear method uses a Load and Resistance Factored Design (LRFD) approach.

Post-Process techniques – Stress linearization and Stress Classification Lines :

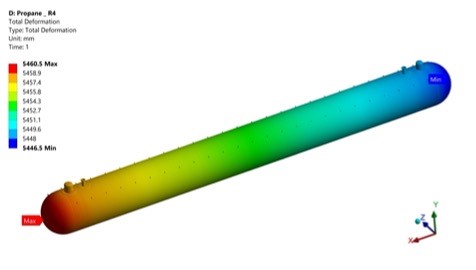

In failure modes due to Plastic Collapse and failure due to fatigue or Cyclic Loading, one of the methods provided in ASME Section VIII Div 2 Part 5 is a linear-elastic method. Because not all stresses will contribute to plastic collapse of the pressure vessel, however a stress-at-a-point limit is not meaningful.

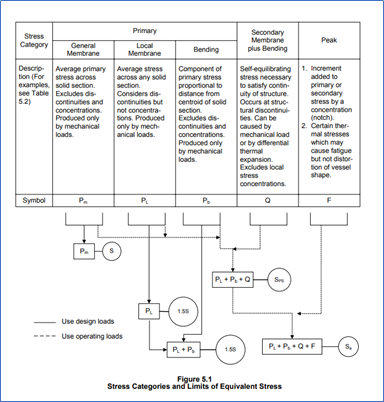

Therefore, the stresses are calculated in FEA in specific locations called Stress Classification Lines (SCL), which are further linearized and classified by this technique. Then, those linearized and classified stresses at each location or part are compared to appropriate allowable stress limits. This is the general basis behind what is known as the Hopper Diagram shown below –

Returning to my original question to conclude this blog. The field of FEA for pressure vessels is rather complex to answer. However, the best way that one can describe is as follows –

FEA for pressure vessels is like a three-legged stool. The first leg is the knowledge of mechanics of materials and the finite element method. The second leg is working knowledge of the particular FEA software. And the third leg is a thorough knowledge of the ASME pressure vessel Code. If the designer is missing just one of those legs, they are sitting on a two-legged stool, which can be dangerous or disastrous sometimes.

We at, Graphler Technology Solutions provide expert pressure vessel analysis services . We also have experts for 3D to 2D Conversion Services, CAD Conversion Services and Product Animation Services.