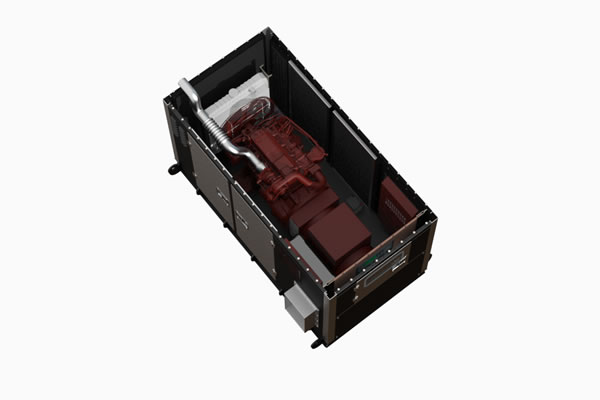

Diesel Generator Enclosure

Industrial design, Structural design, US Military standards, Acoustics, Transportable

A portable diesel generator is something similar to a ground mounted one. It is important the enclosure and the support structure fits in the size of a standard truck width.

Our scope was to develop an acoustical enclosure with less than 90dB insertion loss and support structure which should withstand 20g shock loads and acceleration loads as per US MIL 520g standards.

The second important aspect for the enclosure involves the heat ventilation characteristics. The requirements of cooling air, heat exchanger sizing, louver sizes and filter static pressure were taken into account.

We started off with selecting the right sound absorbent material, a passive control method to reduce the amount of sound transmitted through the enclosure to the space of interest. A sound absorbing material is selected based on its ability to attenuate sound pressure waves. Multiple layers of acoustic foam sandwiched between the metal panels. These foams also have very less specific heat capacity and thus it can radiate heat to the surroundings effectively.

A perforated panel with small air space between the foam and panel is provided inorder to attenuate low frequency sound waves. The perforated panels with small diameter holes acts as a resonator to impede noise. To evaluate the effectiveness of the acoustic foam and perforated panels, numerical acoustic analysis was performed and design was iterated based on the results until the requirement is achieved.

Inorder to achieve very low noise levels the enclosure would become thicker and heavier and thus increasing the weight of the enclosure while placing emphasis on weight of the enclosure will yield light-weight enclosure but poor acoustic capabilities. Weighing parameters were put in place and compared with data from analysis to design an optimal enclosure.

Base frame is where the enclosure and engine is mounted, the structural frame is designed for loads specified in US MIL 520G (United States Military standards) for in-frequent loads during transportation on a truck platform.

The heat ventilation design began with operating temperatures of the engine placed in a free-field environment. With forced air flow and maximum electrical load, the enclosure is simulated using CFD codes to determine the temperature on engine walls, cylinder head, alternator, exhaust etc. the surface averaged temperature is compared with operating temperature determined by the engine manufacturer – Cummins 10kW.

Contact us to discuss how we can help you with your next Product development endeavour