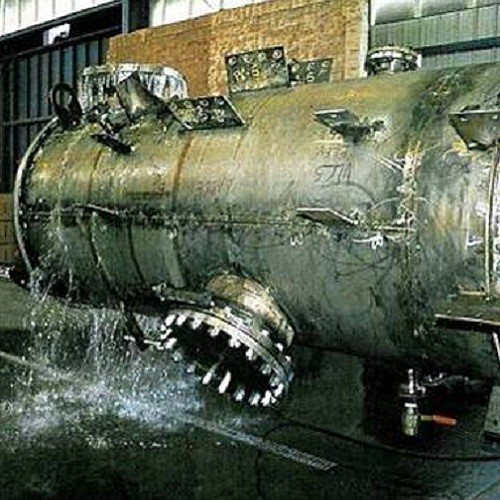

Mounded Bullet tanks are horizontal cylindrical tanks to store large quantities of Butane, Propane, Liquified petroleum gas (LPG) and other highly inflammable gases. Mound over the tanks eliminates the Boiling Liquid expanding vapour explosion (BLEVE) and also protect the tank from fire engulfment, radiation of fire and vandalism.

The Mounded Bullet tanks are designed as per ASME Sec VIII Div-1 and Div-2, BS 5500, PD 500 and EEMUA 190

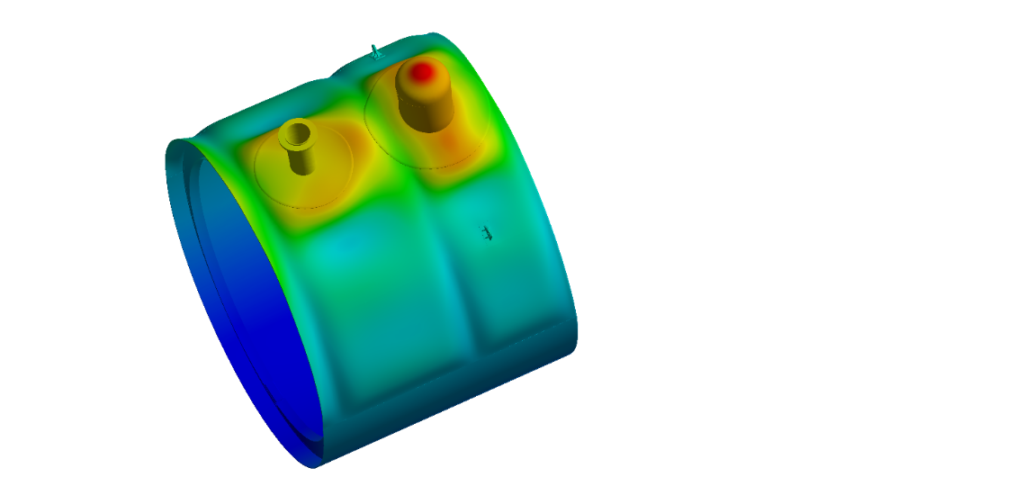

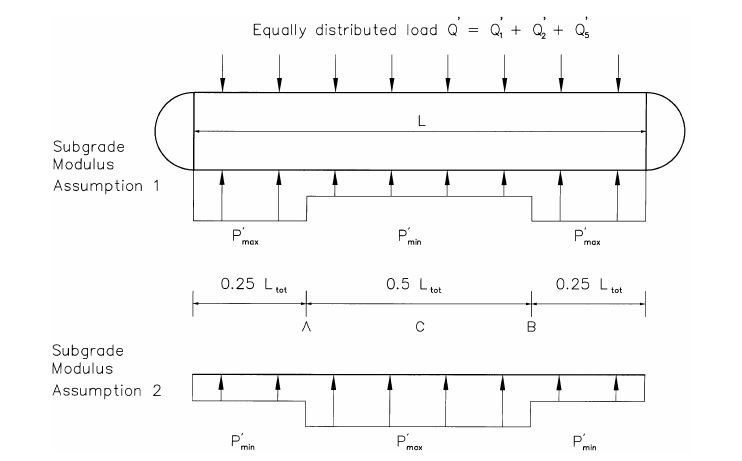

Here in this article, we shall discuss on the analyses as per EEMUA 190. Through the design calculations the preliminary design of the vessel is made for the decided external and internal pressure. Then the following analyses are performed through FEA (New Product Design and Development using ALD) to validate the design and optimize the thickness of the shell and dish ends, number of stiffener rings and nozzle strength.

To know more on evaluation through ASME Sec VIII Div 1 and 2 – FEA evaluation of Pressure Vessels – ASME BPVC Section VIII Div-2

On step by step evaluation of the storage tanks, weak spots and optimization zones are infered.With our in-house team – 3D modelling and 3D to 2D conversion services team with experise in Heavy engineering and Pressure vessel analysis and storage tank development, we update the design and re-iterate for design study. On successful validation, we convert the 3D to 2D manufacturing and fabrication drawings as per clientele requirements and formats

Case -01 : Design Pressure Analysis The internal and external pressure plays the vital role in design of all pressure vessels, storage tanks and allied products. The increase in internal pressure than the design pressure may lead to explosion and higher external pressure than designed may lead to other failures like implosions, cracks etc. In this analysis, the internal pressure head of the fluid, weight of the liquid and the tank and the external pressure due to moud are considered and evaluated.

Case -02 : Negative Pressure Analysis

In this analysis the mound bullet tank is evaluated to check the structural rigidity towards implosion. The storage tanks is tested for -0.5 bar pressure unless specified otherwises.

Case-03 : Hydrostatic Test Analysis

In this test the storage tanks are validated with 100% filled water and pressured to the prescribed level to quantify the strength of the shell and dish ends.Hydrotest allows to quantify the structural integrity of the storage vessel.

Case-04 : Burst Pressure Analysis

This analysis is performed to quantify the factor of safety of the storage vessel over the maximum allowable working pressure (MAWP). In general, it is expected to 4xMAWP but may vary due to specification and shall be iterated.

Case-05 : Imbalance Support Analysis

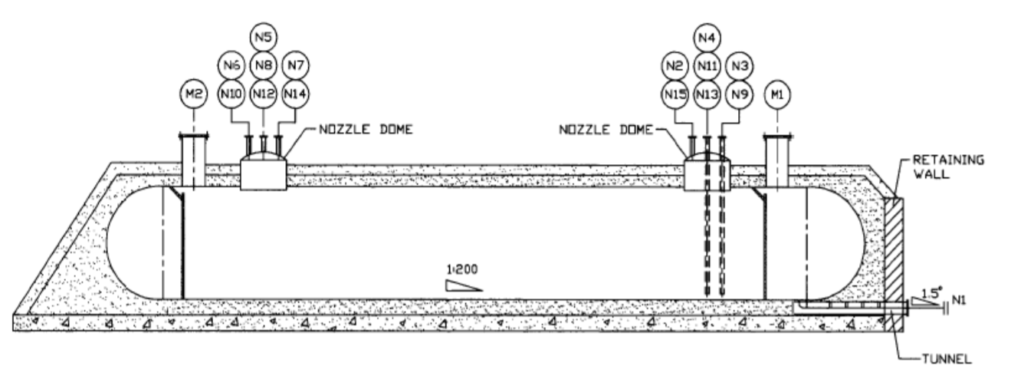

The soil under the bullet tanks are rammed and stiffened to withstand the load exerted by the tank but may not be even and may cause uneven support to the tank. The uneven support are simulated as per the following.

Case-06 : Seismic Analysis

As storage tanks with highly inflammable fluids are of high importance and may cause catastrophic events in case of failure. So the storage tanks should not lose its structural integrity in case of natural calamities like floods, earthquakes and other such events based on location. Depending upon the location and seismic profile the tanks are validated.

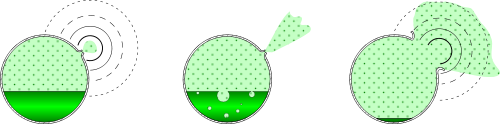

Case-07 : Explosion of gas cloud

The high pressure gas explosion (BLEVE) above the mound may cause sudden increase in external pressure over the underlying storage tanks . It is calculated using the below correlations and validated for failure.

Gas Cloud Explosion load = (2R + ⅔ H) x L x 22.5

Conclusion :

We at, Graphler Technology Solutions provide expert FEA services for Mounded Bullet Tanks. . We have a team of experts specialized in CAD Conversion Service, Engineering Animation Services and more