A product can be a physical or virtual item that serves to resolve customer requirements.

For example, a car is a product developed to address transportation and its comfortability. Based on the required capacity, speed, aesthetics, usage etc the scope of the product development would vary.

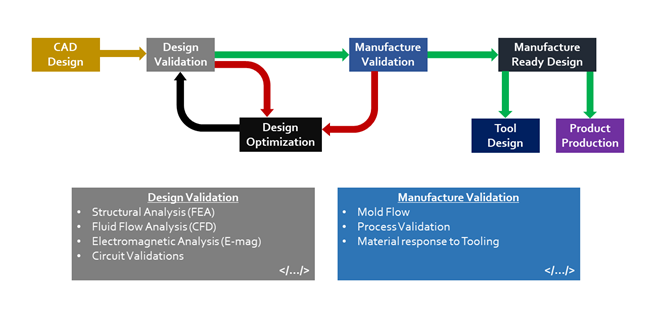

Analyses Led Design:

Analysis Led Design is a strategy that enables to design and develop a product in the virtual environment based on the various constraints and variables. The resultant of the validation analysesen route the development process.

The various virtual tools used in this process are

- CAD for 3D modelling

- FEA for Structural integrity and validation

- CFD for Fluid and Thermal response validation

- CAM for Manufacturing validation

Product design process:

Identification of problem

The problem definition or the scope of the Work (SoW) is the requirements of the customers on a product- function, reliability, aesthetics, quality, cost and user experience. This scope provides the boundary condition of the product development and helps to avert over or under designing the product. Detailed study and concepts would help to understand the real-time impact and response of the constraints and its variables.

Concept design and development

Concept design and development is a process of idea generation through brainstorming and other methods to develop a solution systematically, even though it sounds wild and crazy. Concepts of various technology, systems, mechanisms, aesthetic and ergonomics are used to reach the required functionalities of the product. Combinations of these concepts are worked out and are finally screened to get the better out of the options.

Concept screening

Concept screening and scoring is a process of providing scores and evaluating the worthiness of the concepts. The product objectives are the vital parameters of screening. The concepts developed are valued based on the parameters with a scoring sheet and are compared with each other to get the worthy outcome. Concept screening helps us to shortlist the concepts which are specific, customer-focused, market competitive and effective.

System CAD development

From the screened concepts, the product specification is derived by the functionalities and its combinations for the product variants. In addition to the product spec, complying to standards, usage of market available parts, manufacturing process, material selection is added into the development such that the product begins to take its shape in the 3D modelling software from the sketchbooks. These preliminary CAD designs are volatile due to day to day updates and revisions.

Design Validation

The system CAD design is validated for structural integrity, response to thermal and fluid interactions, E-Mag and Circuit simulations for various critical operating conditions. The results provide insights like the reliability and worthiness of the design. Design Validation averts the over or under designing the product. Design validation is also performed for operational, Live and critical load to comply with industrial standards and safety requirements.

Manufacturability Evaluation

Manufacturability is to assess the ease and feasibility to manufacture the products with the designed shape, dimension and tolerances with the cost bound process line.

Design optimization

Validation helps to find space for optimization and improvement. From the results of the validation study, over and under-designed regions can be aptly reconsidered, function to cost ratio can be increased, shape and stability can be improved.

Detailed CAD development

All compliance to standards, specifications, functional aspects, optimizations and revisions works are incorporated in the CAD. and then the manufacturing drawings, fabrication drawings, assembly drawing and Tool designing are released for production activities.

Graphler Technology, one of the leading Product design companies in India, we are also into many sectors like Heavy Engineering design services, FEA Services India , CFD Analysis services and 3D Modelling Services India .