In the earlier days – the product development process was iterative and was tandem to each other. Each time the product was designed, it was made into a prototype and was tested destructively to know its properties and stepped into the next part of the iteration. This was time and cost consuming. Even today we make prototypes and test the products destructively, but not on the development phase but at the end of it – toverify the worthiness of the product in the real environment.

In the current trend, the product development process is becoming leaner and leaner every day to increase the function to cost ratio and to reduce the Time to Market (TTM). Current market demands- new and intriguing designs, quality functions and more cost-effectiveness. To water the thirst in the market, companies run faster to produce high-quality goods in shorter lead times with a streamlined process like Analyses Led Design(ALD).

To know more about ALD read our previous blog- THE WAY OF ANALYSES-LED DESIGN(ALD) and New product design and Development using ALD. One of the vital methods of validating the design under the Analyses led Design is Structural Analysis.

What is Structural Analysis?

Structural Analysis or also known as Finite Element Analysis (FEA) is a process of validating the structural integrity, strength and behaviour/response of the product under various load conditions. This may be performed over any assemblies or part of the system and evaluated for its load conditions.

Why Structural Analysis?

Products are designed to resolve a definite purpose. In the real world, they encounter various operational, environmental and abusive loads. A good product should be designed to withstand those loads and serve its functionality without interruption. Right? So, we have to validate, evaluate and quantify its reliability to do so. To test those concerns, we quantify the real-world usages of the products and convert those scenarios in the virtual environment and validate the results.

For example, Crash-worthiness of the car is the ability of the automotive to protect its occupants from any directional impacts. To trial this, we cannot make a conceptual car at each stage and run a crash test. Alternatively, the crash scenarios are modelled and are simulated in Finite Element Analysis (FEA). This helps us to tune the design at every stage of design with least time and expenses comparatively.

This not only limits its use in the automobile or crash analysis. It has its application in most of the engineering problems in the product development process. The components are evaluated to find its response to the respective loads.

Types of Structural Analyses?

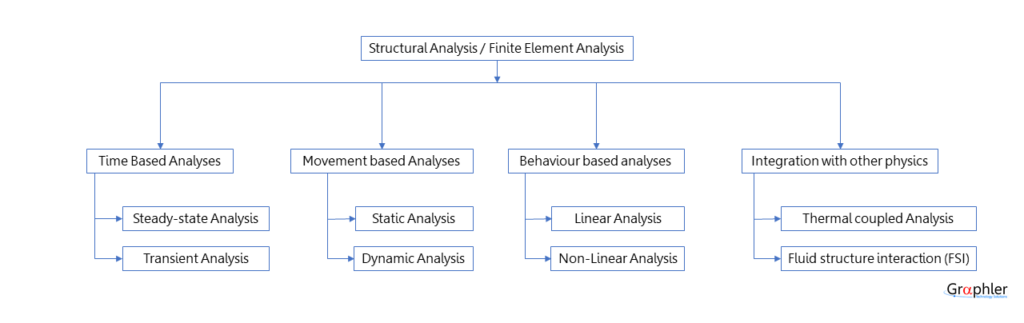

The various types of structural Analysis or Finite Element Analyses are,

- Time Based Analyses

- Steady-state analysis

- Transient analysis

- Movement based Analyses

- Static Analysis

- Dynamic Analysis

- Behavior based analyses

- Linear Analysis

- Non-Linear Analysis

- Integration with other physics

- Thermal coupled

- Fluid Structure Interaction (FSI)

These categories are coupled with each other and enable us to validate most of the operating conditions in real-time and help to model the products with reliability in less time and cost.

Are you searching for the new product design companies in India? Graphler Technologies is specialized in many sectors like Heavy Engineering design services, FEA Consulting services, CFD Analysis services, 3D Modelling Services and in 3D CAD design service In India.