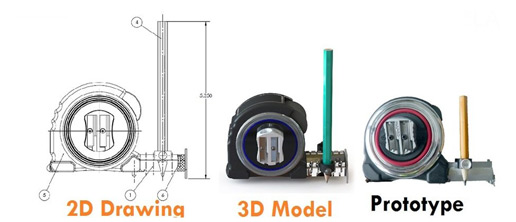

One of the main challenges that every product companies/designers face is not having the capacity to show their clients how the envisioned design of their product will look like and work in real world situations. It is therefore necessary and important to prototype engineering in every Product development phase. However, the process of developing a working prototype is tedious and must include countless of tests and research from all walks of engineer.

Prototypes are an essential step in the development of a final product. By making different prototypes, the designers can work with different iterations of the same product and see how it would look and perform in real life. With all the tests, trial, and errors done on the prototypes, the product engineers can modify the design and then push it forward for the final production.

Prototype manufacturing and rapid prototyping have many different benefits. Some of the main benefits are discussed below;

Freedom to make changes to design almost instantaneously

Once prototype development is finished, a physical model of the design can be seen visually. With a visual model, any changes to the design can be done almost immediately by merely asking for feedback from the stakeholders. This allows many different iterations of the design before it becomes production-ready. Such iterations allows the designer of the product to make it better and efficient as compared to the one at the start.

Having an actual prototype in hand, gives confidence of both the designers and the stakeholders.

Cost-efficient and less time consuming

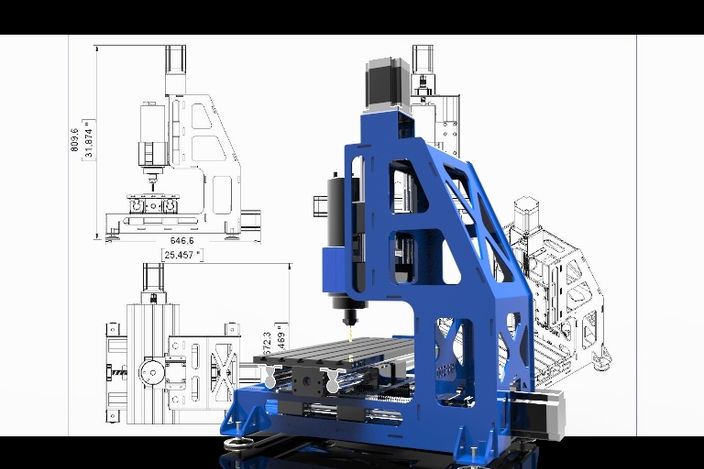

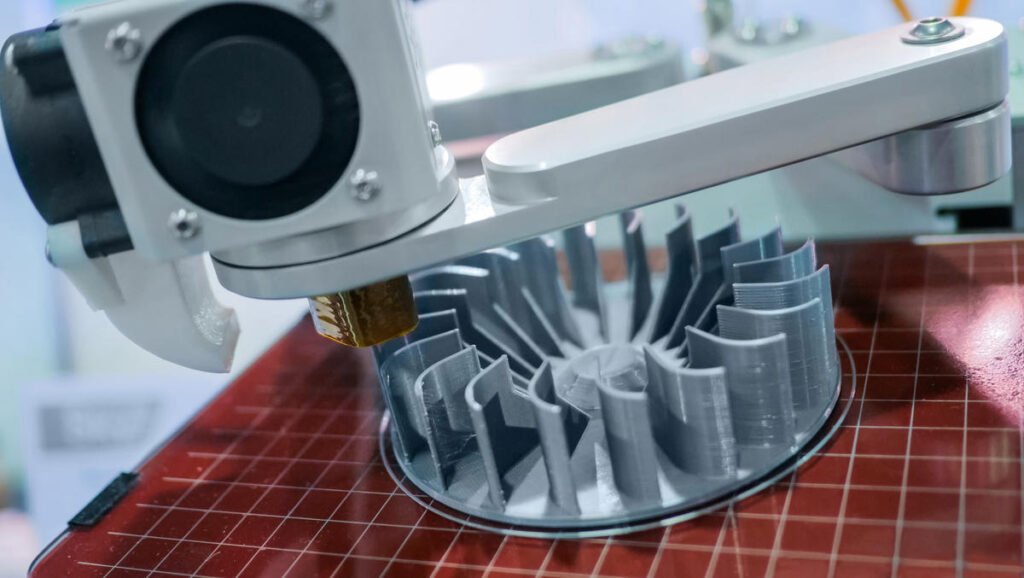

With rapid prototyping, a huge chunk of time and cost is saved. The time and cost required to make new patterns and die for every new different prototype manufacturing are eliminated. One of the main reason for this is because rapid manufacturing makes use of additive manufacturing tools such as 3D CAD. Such measures are not only quicker but are also cost-efficient. As opposed to conventional prototype development, this process is more efficient and wastage of raw material is kept to the minimum and any waste material can also be used back in some cases.

The issues with the designs such as aesthetics, fit, and assembly are identified and modified at a very early stage, the issues can be rectified before final production. If a prototype was not made for a product and the design is pushed forward to production, it is possible that the manufactured product would have the fault, identified only at the customer end. This would render the whole batch of products to be useless which would be a cost and time burden to the company and as well as a disappointment for the customer.

Highly Customizable

One of the most promising benefits of prototype engineering is the high level of customization that it can offer. Every prototype can be altered in design and shape, tested for various field conditions and no matter how complex or hard the design is, one way or another, the manufacturing processes can be identified and once approved, the final efficient process can be identified.

Since modern prototyping engineer uses CAD to create virtual prototypes before making a physical form of it, a small change in the geometry is possible without altering the other parts of the design. This allows the engineers to tweak the design for its functionality and structural requirements.

Identify flaws before the product is approved for production

Manufacturing of prototypes before the final go to production model allows for any design flaws to be identified and corrected beforehand it reaches the customer. Physical design flaws and fit-finish, though can be studied and controlled in virtual designs, however, one may not infer how the product would behave and perform in real-life scenarios which are otherwise hard to determine virtually. Therefore, an actual prototype can be tested in a number of real-world conditions and verify how it would perform. The risks of usability issues and failures are mitigated to a higher level.

Conclusion :

Graphler Technology is one of the fastest growing product design companies in India, focused on taking new product ideas right through to prototype development and manufacturing . We have created 100s of products right from the scratch to production for clients worldwide. We have a team of experts specialized in 3D to 2D Conversion Services, Product Animation Services and Pressure Vessel Analysis Services .

Contact our experts today to know about our services.