3D CAD design and technology has a significant role in the transformation of Digital Manufacturing and Industry 4.0. It offers a wide array of advantages including flexibility in design and optimization, discovering the swift and simple route to implement the innovative ideas and technology with a very low margin for errors, rich design context, feaster route to manufacturing/production.

Why move from 2D Drawings to 3D CAD Models:

2D Drawings are made in the ideologies of manufacturing incorporating basic components and manufacturing needs – that leaves room for errors and time delay. Converting that ‘ 2D to 3D CAD models’ files opens a wide range of manufacturability, space for improvement and development, and eliminating the cons in 2D.

Graphler Technology Solutions offers 3D CAD as a service (CADaaS), which would open up new opportunities for product development. Graphler creates 3D CAD files as per customer requirements, protocols and format. We at Graphler ensures quality in design, eliminating errors and happy customers. And also, we provide suggestion and development assistance in the product to improve the strength, optimization through VA/VE (Cost, material and Process optimization) through Analyses-Led Design (ALD).

2D Drawings to 3D CAD conversion – Best Practice:

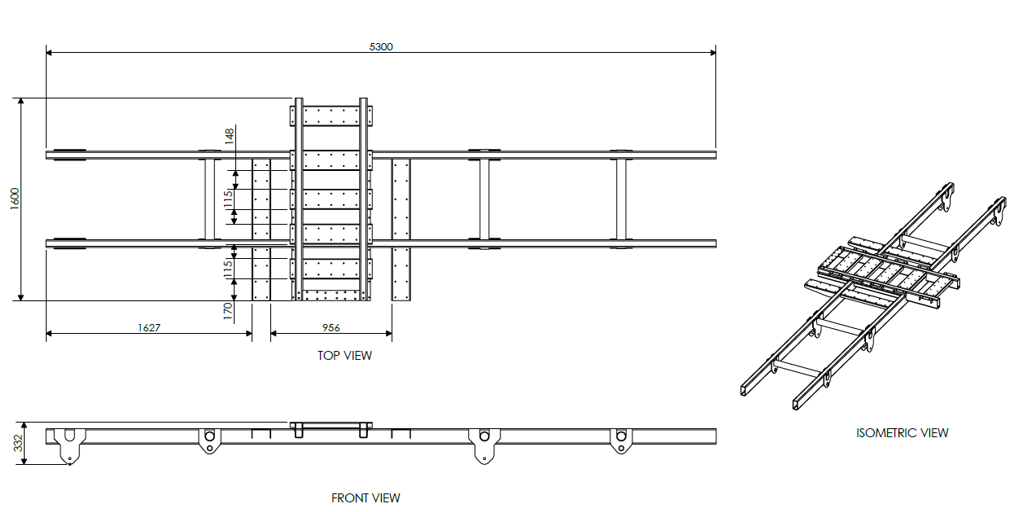

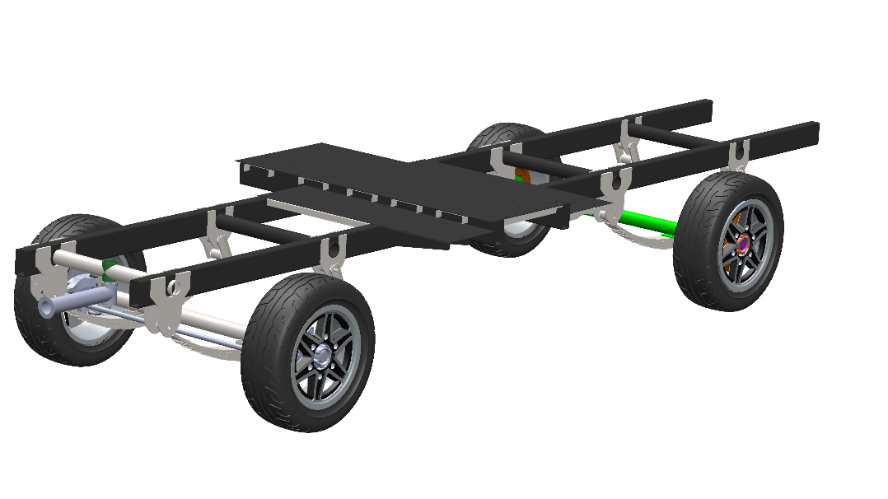

2D drawing of the products provide information like cross-section, dimensions, special details etc. which are important for manufacturing whilst 3D CAD model with parametric felicitates flexible design updates on component and assemblies and visualize the end product outcome

2D Drawings provides annotations and representation for ease of understanding and manufacturability. The 3D component shall also be developed based on the manufacturing process in which the component is intended to manufacture.

Sheetmetal, Plastic, Weldments, castings and Forming are some of the subsections in which the design of the component. Based on the manufacturing process the parts have to be developed. For example, Sheet metals should be designed in the prospects of bending and its allowances, tool availability etc.

3D modelling of the component is not only about the extrude, revolve and other basic works, the part development should be done with the knowledge of the manufacturing process, allowance, tolerances and assembly process.

Knowledge of Design for manufacturing and Assembly (DFMA), Geometric Dimensioning and Tolerance (GD&T), and Material strength and response are key to develop.

We at, Graphler Technology Solutions provide expert CAD services – 2D to 3D CAD conversions, 3D to 2D Conversion Services, CAD Conversion Services, Drawing development based on the manufacturing and standards based on customer requirements and Legacy conversion with excellent engineering prospects and quality. With our expertise in Structural analysis, CFD analyses and Product design and development – we offer the best solutions to build, develop and optimize the products.