INTRODUCTION

High Velocity Oxy-Fuel(HVOF) Spray is used to coat corrodible components with resistive materials. It utilizes highly compressed fuel that combust with oxygen to accelerate the momentum and temperature of the particle and also to make the flow supersonic.

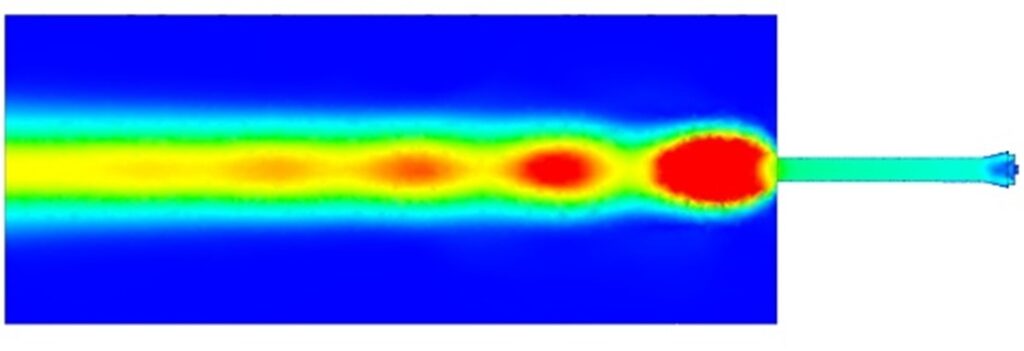

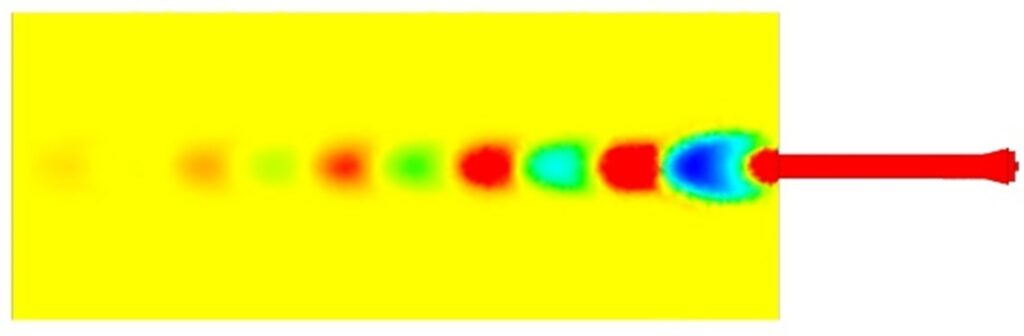

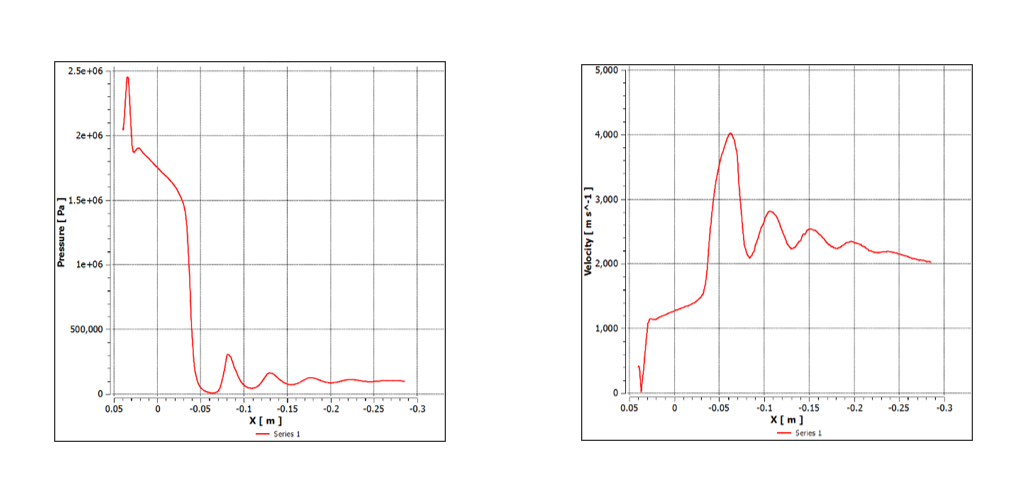

Supersonic nature of flow in an atmospheric condition producing sequential pressure expansion and contraction letting out a phenomenon called Shock Diamonds. These Shock Diamonds a.k.a pressure pulsations produced due to hyper pressure gradient with respect to atmospheric pressure.

With the aid of the CFD technology, the complex Pressure Gradient of supersonic flow nature can be vividly captured and the design progress can be accelerated. Thus, CFD is an important tool for Flow physics as it will reduce the time consuming and expensive experimental procedures.

SCOPE OF THIS RESEARCH WORK

- To model the combustion of fuel and oxygen in a compressed chamber.

- Get a higher temperature and velocity pulsation proportional to pressure pulsation.

- Injection of spray material using Discrete Phase Modelling (DPM).

MODEL ACQUISITION PROCESS

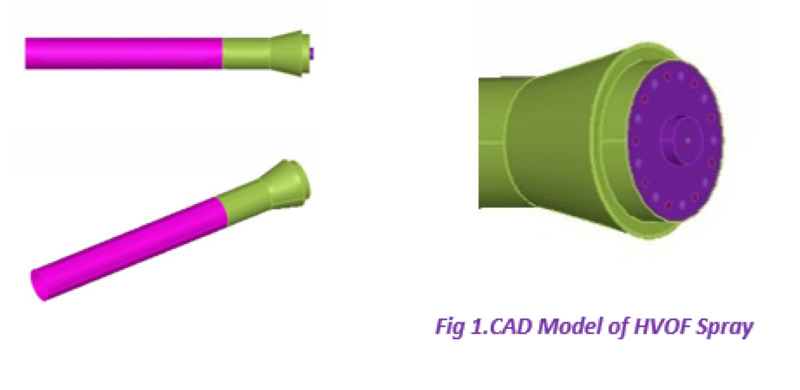

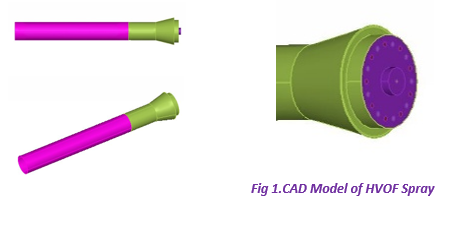

The HVOF Setup is experimentally analysed in Annamalai University, Chidambaram. From the resource the component is manually measured and the model is generated in CAD software package Pro-E Wildfire 5.0.

CFD ANALYSIS

With a goal of capturing shock diamonds of the supersonic flow of HVOF Spray, CFD is utilized in a following systematic way.

The best way for you to get the necessary information is by contacting a reputable CFD Consulting Services or a Structural Analysis Services provider.

VALIDATION STUDY

CFD procedure has lot of variables such as grid count, turbulence model, and discretization scheme, so it is important for a CFD engineer to play between those variables without affecting the solution accuracy. A commercial Computational Fluid Dynamics (CFD) code, ANSYS CFX V14.5 with a k-ε Standard turbulence model with Eddy Dissipation Model for combustion was used and the impact of supersonic flow in an atmospheric pressure and the Pressure pulsation was obtained.

The numerical results are compared with the experimental data to arrive at the best computational procedure (BCP) and Discrete Phase Modelling (DPM) is proceeded to introduce the surface coat material into the domain.

INFLUENCE OF CFD TECHNIQUE IN THIS PROBLEM

The Shock Diamond occurrence mainly depends on the hyper pressure difference between the atmosphere and combustion chamber. It depends on the flow rate of fuel, oxygen and volume of the combustion chamber.

Working with a leading Stress Analysis Services provider or well-known Product Design Companies will make new routes possible.

*** No experiment will provide an INSIGHT views like the pressure contour, velocity vectors in different planes and positions as shown in Fig 2, Fig 3.

***Above Figures shows the pulsation of supersonic flow of fluid in atmospheric condition. And it is impossible to get this much detailed view of velocity and pressure profiles when we go for experiments so this is the place where one can see the merits of CFD techniques.

CONCLUSION

- A Special phenomenon of Fluid flow is acquired in computational methodology

- Surface Coat material injection and Combustion of fuel-oxygen is modelled