Introduction

Banks and other entities are continued to be challenged by the increase in demand for energy utilization of commercial made air-conditioning units for cooling of ATM centers & data centers. In operational perspective, this means more energy is utilized and thus more the running over-head cost per year.

In this case, the existing cooling infrastructure may not be suitable or efficient which make those involved in ATM and data center must integrate design and operational priorities to ensure long term viability of their facilities.

Importance of efficient cooling in ATM & data centers

Computer servers, telecommunications equipment and storage systems housed in ATM & data centres dissipate an enormous amount of heat – and the equipment must be maintained at acceptable temperatures to assure reliable operation to prevent equipment failure due to overheating.

However, in many cases facility cooling infrastructure suffers from inefficient operation, which leads to decreased energy efficiency and over-provisioning of cooling equipment. That inefficiency can result from several different factors. For example, the cooling airflow is not distributed according to the demands of the equipment, or the discharged hot air is not properly contained or vented.

With continuing increases of heat generation in ATM & data centres, plus dramatically rising energy costs, banks and other entities are coming under greater pressure to improve the efficiency of cooling systems and reduce power consumption.

Why Computational Fluid Dynamics (CFD)?

Computational Fluid Dynamics (CFD) technology provides a more scientific and comprehensive design approach to thermal and power management. CFD technology can be applied to create a better understanding of flow path inside the centre and illustrate the effects of equipment layout, location of cooling unit, under-floor obstructions and temperature distribution inside the centre.

CFD modelling would enable data centre mangers to accurately depict and understand the use of cooling resources and allow for appropriate infrastructure right-sizing. This could significantly help prevent organizations from under- or over-provisioning the infrastructure. Instead of buying cooling equipment they do not need, they might discover that they can simply reposition what they have.

Contact a well-known CFD Consulting Services or a Structural Analysis Services provider to acquire the required information.

Conventional practical solutions

It’s currently estimated that, on average, 5-10 percent of company’s budgets are dedicated to energy costs. This percentage will rise, inevitably. It seems that government mandates will soon force facilities operators to reduce energy consumption. Many companies are already evaluating and/or implementing alternative solutions to reduce their energy use and make data centre cooling processes more efficient.

Understanding where to place the equipment to maximize airflow in an operational data center is typically done through trial and error or empirical guidelines based on limited measurements.

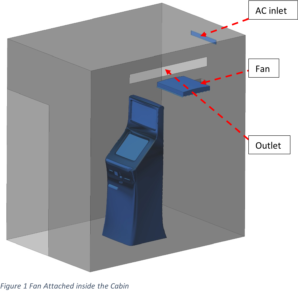

- Flow pattern inside a general ATM cabin is studied using CFD technique. In this study, air flow from AC duct is applied into the cabin to study the flow nature and the operating temperature range over the ATM machine.

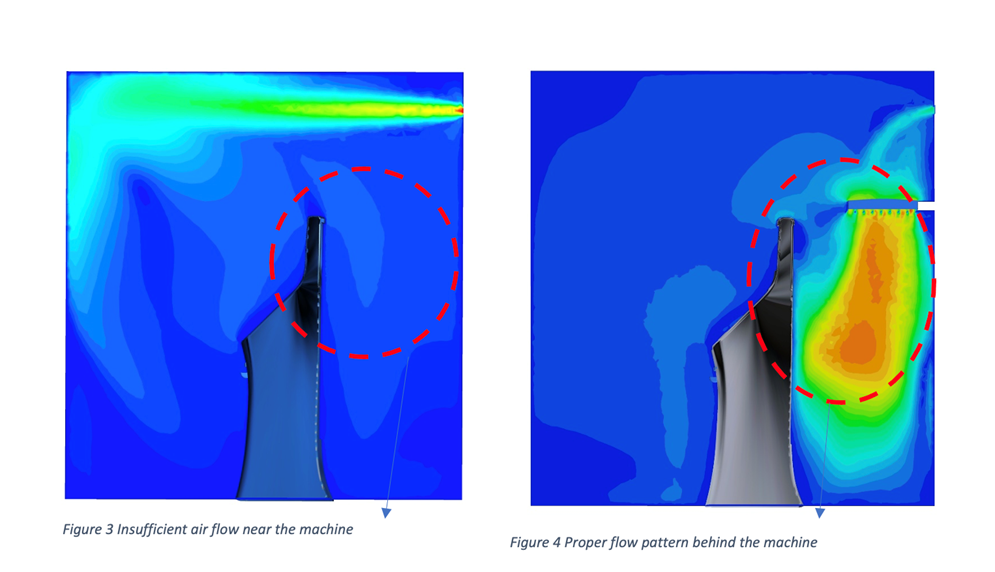

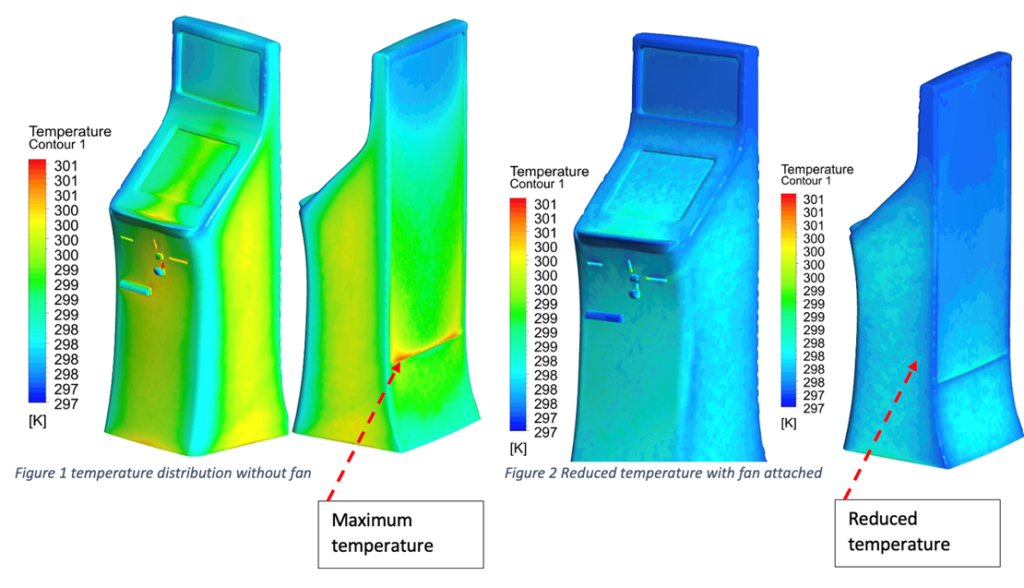

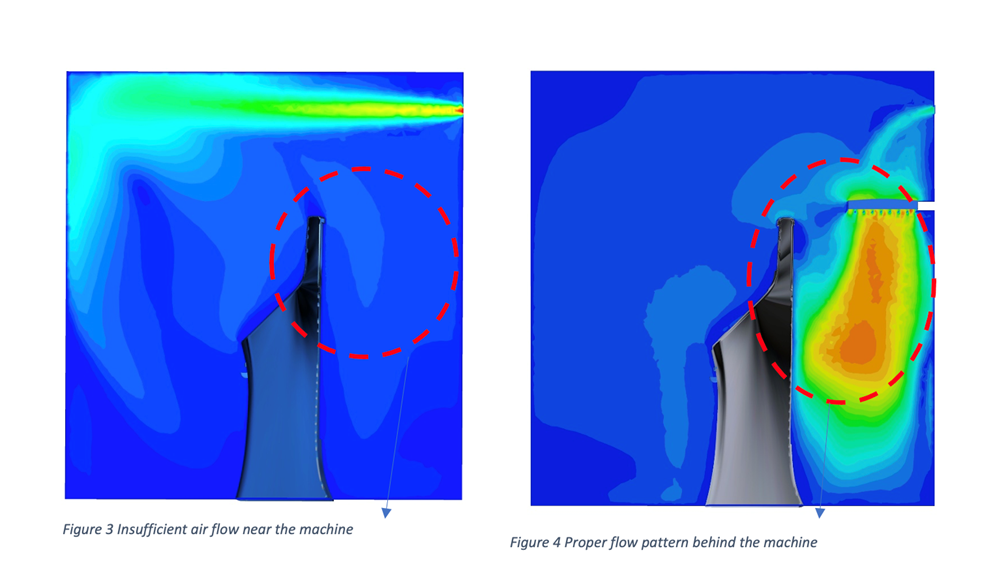

- In order to have a good air circulation a fan is introduced under the AC duct as shown in figure 2. And the suction through the fan is found to have a good flow pattern and reduced temperature distribution over the machine as shown in figure 6.

Loss of Insight

These methods often do not consider the complex fluid dynamics that govern air flow distribution, and consequently do not produce the expected flow rates. An adjustment in one section of the data center will affect flow rates throughout the other areas. This kind of design procedure is labor-intensive, time-consuming and expensive –and still seldom yields an optimal, efficient solution.

And this is the place where CFD comes into picture through which one can get a clear insight of flow nature inside the system and can providing a better design changes without expensive experimental procedures.

Collaborating with the best Stress Analysis Services provider or top Product Design Companies will open up new ways.